COMARK’s water production lines are tailored to meet the unique demands of modern water bottling operations, providing flexibility and efficiency across the entire manufacturing process. Our machines are engineered for versatility, allowing businesses to quickly adjust production settings based on specific requirements, such as bottle shape, size, or material. COMARK’s equipment is built with energy-efficient components, designed to reduce operational costs while maintaining high-speed production. The automated design not only increases production capacity but also ensures that each bottle is filled accurately and consistently, helping businesses meet strict quality control standards. Additionally, COMARK’s water production lines are designed with ease of maintenance in mind, with durable components that ensure long-term reliable performance. Our comprehensive after-sales support and technical assistance ensure that your production line continues to operate smoothly, minimizing downtime and maximizing profitability. For companies looking to optimize their bottled water production while maintaining exceptional quality, COMARK’s water production lines offer the perfect solution, combining advanced technology with robust, reliable design.

Handling turn-key projects for water bottling, COMARK also produces bottling lines. Modern production requirements for CONMARK’s production lines are such that any operation in the cycle of bottling water – filtration, purification, filling, capping, labeling and so on is incorporated into and consecutive towards an effortlessly operational process. This detailed procedure removes renders businesses the urge for sacrificing high output and its quality levels. The machines of COMARK use advanced technology in the design of their machines to make sure that every process is automated and efficient. Specializing in still water, mineral water, or other beverages, COMARK has engineered filling and sealing systems that employ clean, safe, and accurate techniques. Our production lines can be implemented in small, medium and large production volumes, since they are modular in design. COMARK welcomes efficiency in quality control, assuring that production does not violate set standards and that the materials used in the production process are not wasted while downtime is minimized.

At COMARK, we appreciate that each water bottling operation has its specialization, which is the reason there are water production lines that can be tailored for various types of production. Our machines allow for multiple forms, sizes, and materials for bottles as the manufacturers need the latitude to be responsive to the changing market aspects. The design of water production lines by COMARK also utilizes gas saving where high speed production is attained without incurring high power costs. Our machines are compact because the systems are automated thereby requiring less effort on setups, fast changeovers and little maintenance to enable businesses be dynamic to production level changes. With COMARK, businesses also enjoy the long servicing and high quality components that are offered resulting to maximum reliability from the plans. Our water production lines integrate efficiency technology combined with an emphasis on energy savings which makes it the solution to companies modernising their bottling methods as well as lowering the costs.

COMARK is famous for its water production lines that are reliable and efficient. The determination of the brand can be seen in how strong they are made and what they are capable of doing. Every water production line manufactured by COMARK goes through thorough testing so that it should be able to handle mass production without breaking down often. The controls are advanced and the materials used are of high quality which supports stable performance by these machines even in tough environments where uniformity of outcomes is required over time. With COMARK, businesses can expect nothing less than equipment meeting beyond merely satisfying industrial norms thus guaranteeing continuity throughout manufacturing operations without any hitches.

In order to be more sustainable and efficient in water production lines, COMARK has extended its commitment towards environmentally friendly practices. The production line is designed to save resources such as energy and water hence cutting on operational expenses as well as reducing the impact on the environment. Sustainable production systems are supported by process efficiencies brought about through sophisticated technology which also reduces wastage within the system itself. COMARK ensures that companies are able to achieve their manufacturing targets without violating any laws related to preservation of nature because it concentrates on green alternatives only. This particularity of being concerned with sustainability makes COMARK a pioneer among partners within this sector thereby contributing towards economic growth alongside environmental conservation.

Zhangjiagang COMARK Machinery Co Ltd has specialized in the export of beverage production line for 15 years. We specialize in providing customers with complete beverage(water, juice, carbonated soft drink, energy drink, ice tea and other) production turnkey projects for PET bottle,aluminium can, glass bottle.

We can provide following services:

1-all machines of complete production line

(water treatment system / mixing system / washing filling capping machine / laser code printer / labeling machine / packaging machine / bottle conveyor)

2-Provide raw material such as preform,cap,can, label, PE film and so on

3- About the machines installation, we have professional engineer who go to local, they will finished installation and train your engineer and workers

4-can design label, bottle shape and machines layout according your workshop

Comark Machinery leads beverage packaging R&D, delivering solutions. Dedication to upstream & downstream research ensures a full range.

Serving 30+ countries, Comark caters to industries like drinks, flavors, cosmetics, beer, milk, & pharma. Global reach & versatility strengthen their market position.

Comark focuses on tech innovation, filing patents & fostering a unique market position. This commitment keeps them ahead in beverage packaging.

Comark collaborates with top institutions to analyze & incorporate foreign tech, optimizing design & performance for remarkable improvements.

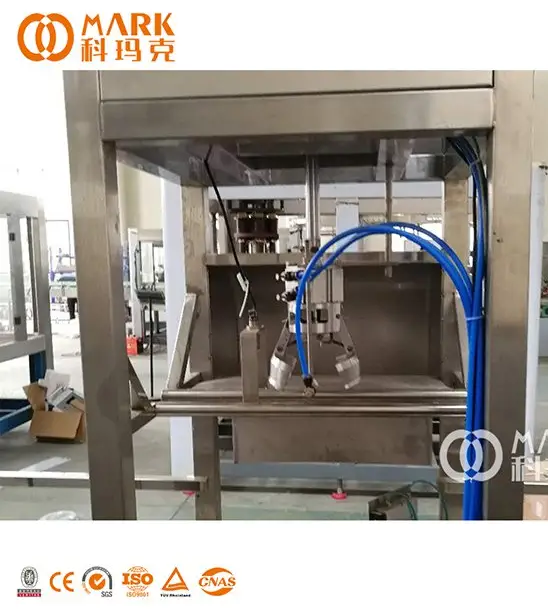

The COMARK Water Production Line typically includes a water treatment system, filling machines, capping machines, labeling machines, and packaging equipment. This comprehensive setup ensures a complete and efficient bottling process.

The production line features advanced technology for each stage of the process, including precise filling and capping mechanisms. It integrates quality control systems that monitor and maintain product standards throughout production.

The production capacity varies based on the configuration and specific models used. Generally, the line is designed for high-volume production, capable of handling large quantities of water bottles per hour. For exact capacity details, please refer to the product specifications or contact our sales team.

Yes, the production line can be customized to meet specific requirements, including different bottle sizes, types, and production speeds. Our team works with clients to tailor the line to their unique production needs.

Regular maintenance includes routine inspections, cleaning of equipment, and calibration of the various systems. A detailed maintenance guide is provided, and our technical support team is available for additional assistance to ensure optimal performance.