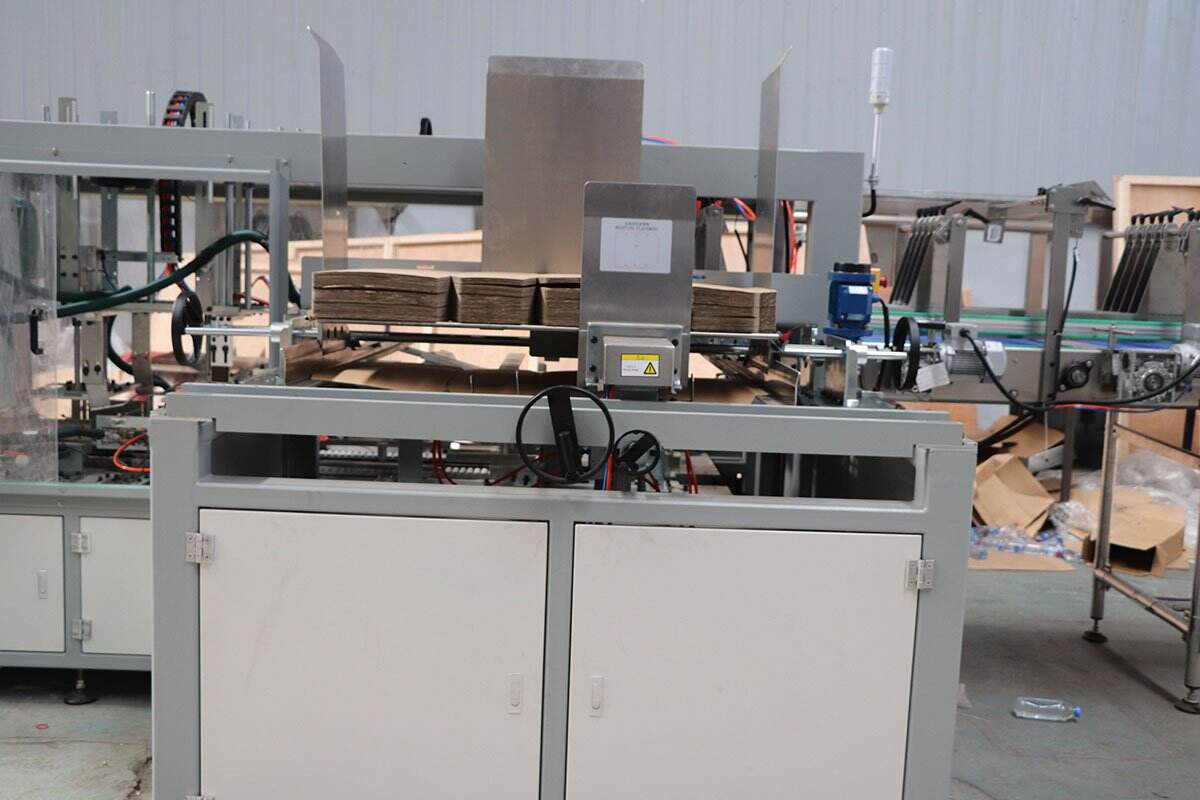

Carton Packaging Machine

Description

comark downstream packaging system widely used in beverage, beer, food, cosmetic and other industries, Based on customers' different needs of bottles, cans, boxes, film bag and so on the different forms of package in secondary and packaging, according to the whole line each unit real-time operation dynamically balanced adjustment, thus it can effectively improve the whole line operation efficiency.

Application:

l Soft drink, liquor (beer, rice wine and alcohol, etc.)

l Liquid food (edible oil, vinegar and soy sauce, etc.)

l Daily commodities (detergent, shampoo and so on)

Capacity: 10-25 packs/min

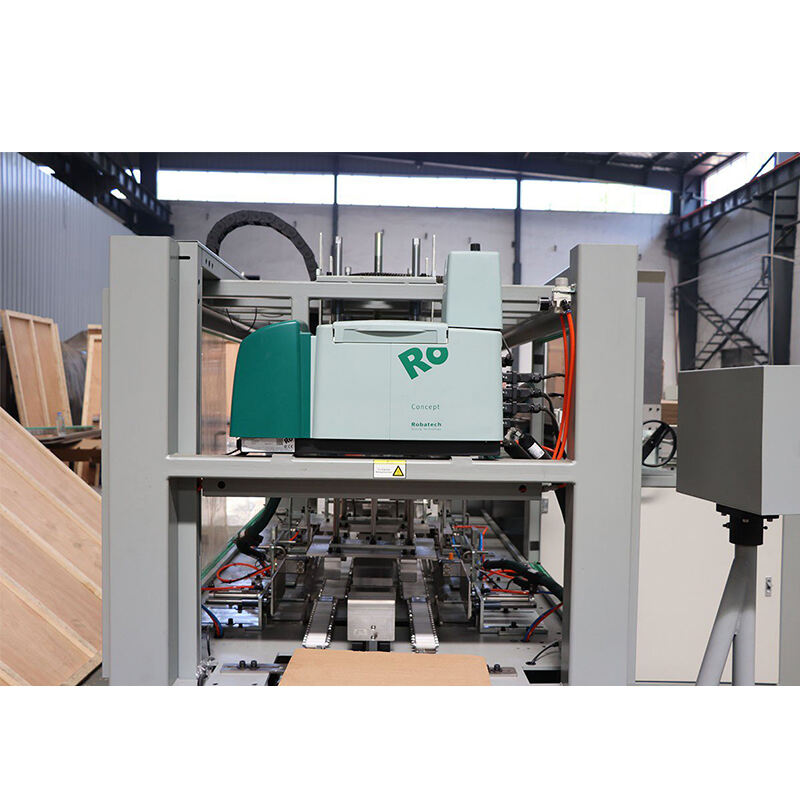

The machine adopts to servo location, PLC controlling, auto operation, main drive adopt to import motor drive, multi degree rotation via chain, chain wheel speed regulator, ect. It auto degree is high, reliable controlling, easy to adjust, intelligentize manipulation, ect., which can be widely used for industries like beverage, beer, chemistry, food, medicine, ect., can do all kind of tin and bottle second time package, can match with auto filling production line.

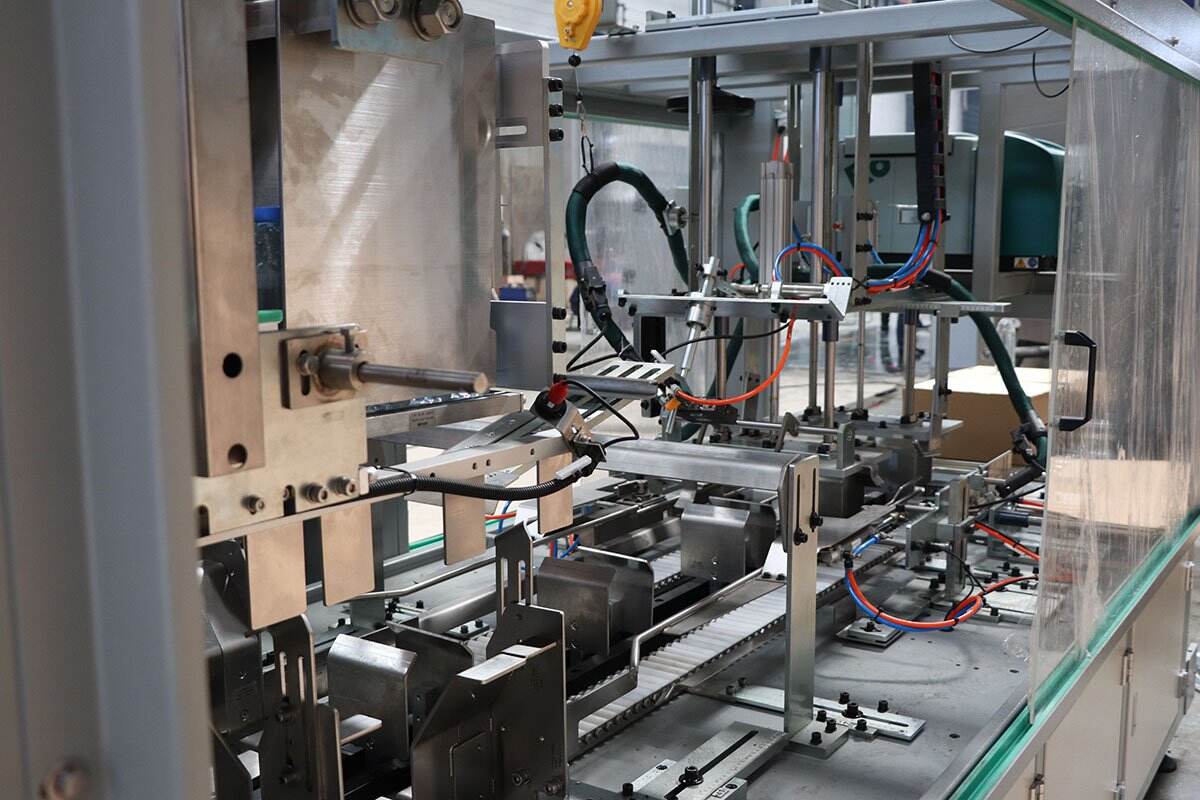

Bottles are separated to multi channel at conveyor, and then group by bottle separate fracture evenly. Bottle are grouped , then drop to cardboard via bottle drop fracture. At drop fracture with bottle and cardboard fall procedure, via one group of form block board, then card board fold to carton form. Via main drive with carton move forward, at the same time, via glue spray fracture to finish carton top glue spray, again the cam fracture via top ledge fold, at the same top carton fold to finish top sticking. Carton move forwarder, again via glue spray fracture to finish carton side glue spray, and via side pressure and carton press fracture to finish carton finally form and sticking, and via main drive let carton move forwarder to conveyor ...