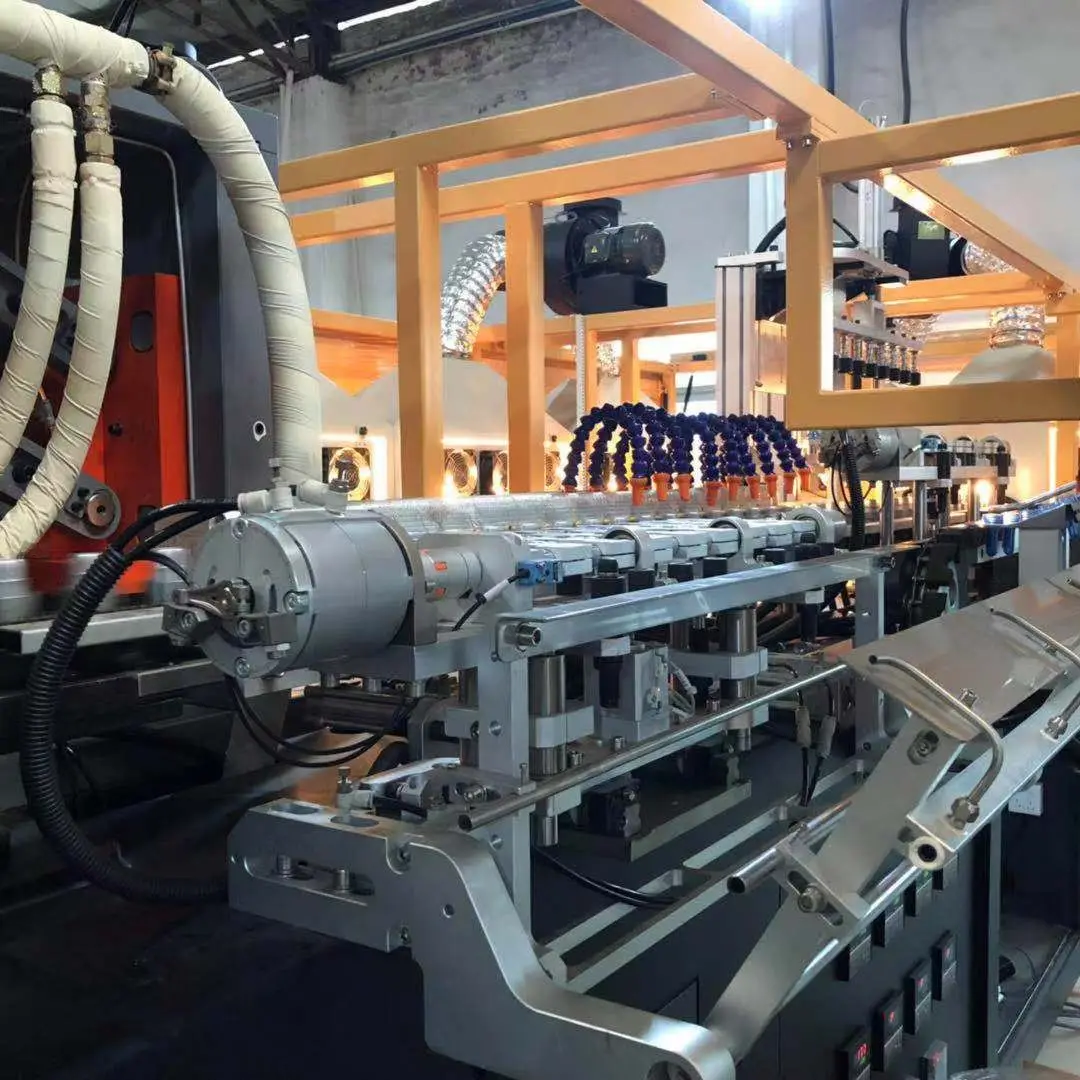

Plastic product manufacturing requires precision and durability, which is provided by the COMARK Blow Moulding Machine. This machine employs the most recent technology hence giving it the ability to produce plastic products of high quality with consistent accuracy. It comes equipped with advanced characteristics that allow different types of molds to be used during production; this saves time as well as making it possible for one machine to handle many different batches. In other words, if there are several production runs which require diverse kinds of molds then all such needs can easily be met using just one unit of this machine. Its heavy-duty design ensures reliability over extended periods even under harsh conditions where other models may fail frequently due to wear and tear caused by continuous use under demanding environments. The user-friendly interface coupled with automated controls makes operation easier while at the same time reducing operational downtime thus making it suitable for manufacturers who want to improve their output capacity within limited periods of time. For instance, whether working on large scale productions or small quantities batches; this device performs beyond expectations because its robustness supports various plastic moulding applications throughout such scenarios without breaking down unnecessarily

Zhangjiagang COMARK Machinery Co Ltd has specialized in the export of beverage production line for 15 years. We specialize in providing customers with complete beverage(water, juice, carbonated soft drink, energy drink, ice tea and other) production turnkey projects for PET bottle,aluminium can, glass bottle.

We can provide following services:

1-all machines of complete production line

(water treatment system / mixing system / washing filling capping machine / laser code printer / labeling machine / packaging machine / bottle conveyor)

2-Provide raw material such as preform,cap,can, label, PE film and so on

3- About the machines installation, we have professional engineer who go to local, they will finished installation and train your engineer and workers

4-can design label, bottle shape and machines layout according your workshop

Comark Machinery leads beverage packaging R&D, delivering solutions. Dedication to upstream & downstream research ensures a full range.

Serving 30+ countries, Comark caters to industries like drinks, flavors, cosmetics, beer, milk, & pharma. Global reach & versatility strengthen their market position.

Comark focuses on tech innovation, filing patents & fostering a unique market position. This commitment keeps them ahead in beverage packaging.

Comark collaborates with top institutions to analyze & incorporate foreign tech, optimizing design & performance for remarkable improvements.

The COMARK Blow Moulding Machine is versatile and can produce a wide range of plastic products, including bottles, containers, and custom-shaped items. It is suitable for various types of thermoplastic materials, ensuring high-quality results for different applications.

The machine is equipped with advanced control systems and customizable settings that allow for precise adjustments. Its high-resolution sensors and automated controls ensure consistent moulding accuracy, reducing variability and maintaining product quality.

The production capacity varies depending on the model and configuration. Typically, the machine can handle high-volume production runs efficiently. For specific capacity details, please refer to the product specifications or contact our sales team for personalized information.

The machine features adjustable mould clamping and alignment systems that accommodate various mould sizes and shapes. This flexibility allows for easy transitions between different production runs and helps maintain high efficiency across different product lines.

Regular maintenance is essential to ensure optimal performance. This includes routine checks of the mechanical components, cleaning of the moulding areas, and periodic calibration of the control systems. The machine comes with a detailed maintenance guide and support from our technical team for any specific needs.