COMARK’s blow moulding machines represent the pinnacle of precision and efficiency in plastic bottle production. Designed for a variety of applications, our machines are engineered to meet the specific needs of the beverage, cosmetic, and pharmaceutical industries. Whether you require high-speed production, customized bottle designs, or energy-efficient solutions, COMARK blow moulding machines are built to deliver exceptional performance and consistency. Each machine is crafted with advanced technology, allowing for precise control over the moulding process. This ensures that every bottle, whether large or small, meets the exact specifications required for your product. COMARK’s dedication to innovation is evident in the flexibility of our machines, which can accommodate a wide range of plastic materials, including PET, HDPE, and PVC. Furthermore, our blow moulding machines are designed to be user-friendly, with intuitive interfaces that allow for quick setup, easy operation, and minimal downtime. With a global network of support and service, COMARK ensures that your production line remains efficient and reliable. Choose COMARK for blow moulding solutions that combine cutting-edge technology with unmatched durability, designed to enhance your production capabilities.

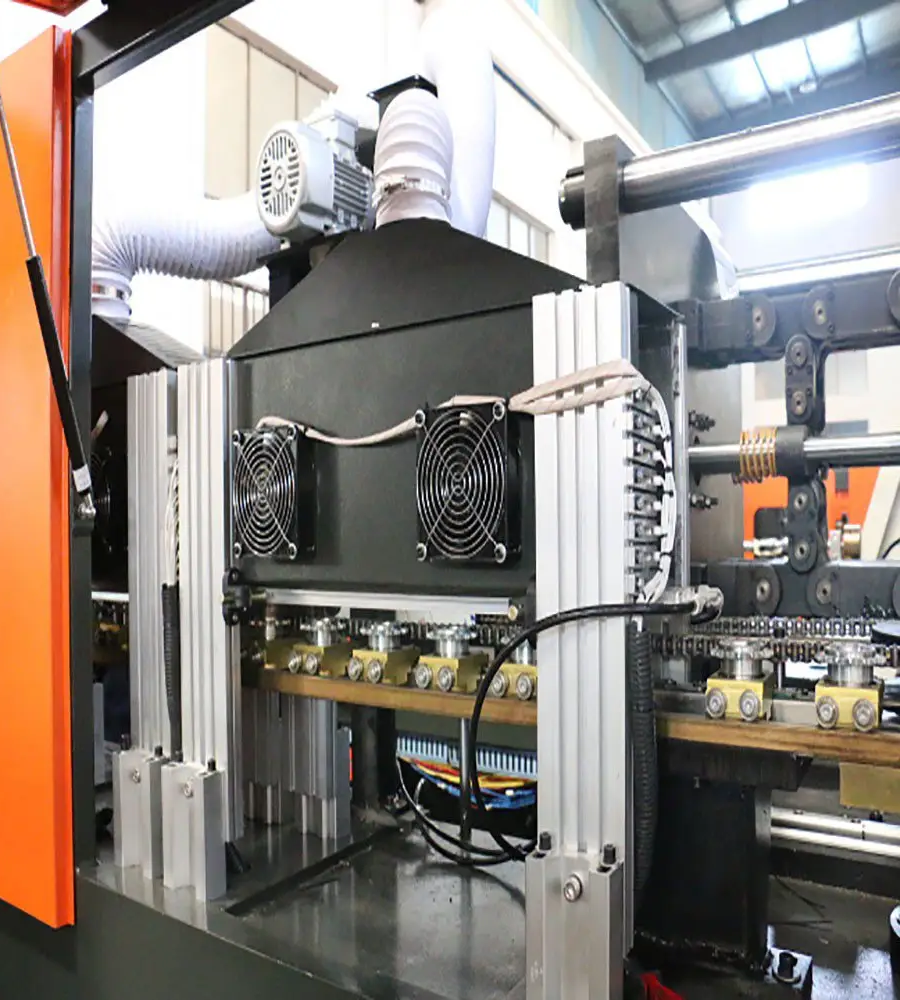

With its blow moulding machines, COMARK prioritizes user experience and ensures they are easy to use and maintain. Every machine comes with a control interface that is easy to understand and operate as well as make quick changes where necessary. In view of this there have been features included in the design which makes it easier for people to carry out regular maintenance thus saving on time and energy that would be used in keeping the equipment at its best working condition always. It is designed in such a way that any operator can manage production effectively without much training or support being required hence making it useful for all skill levels among workers; also this approach allows businesses to maintain high levels of productivity without having to undergo extensive training programs or seek for additional assistance.

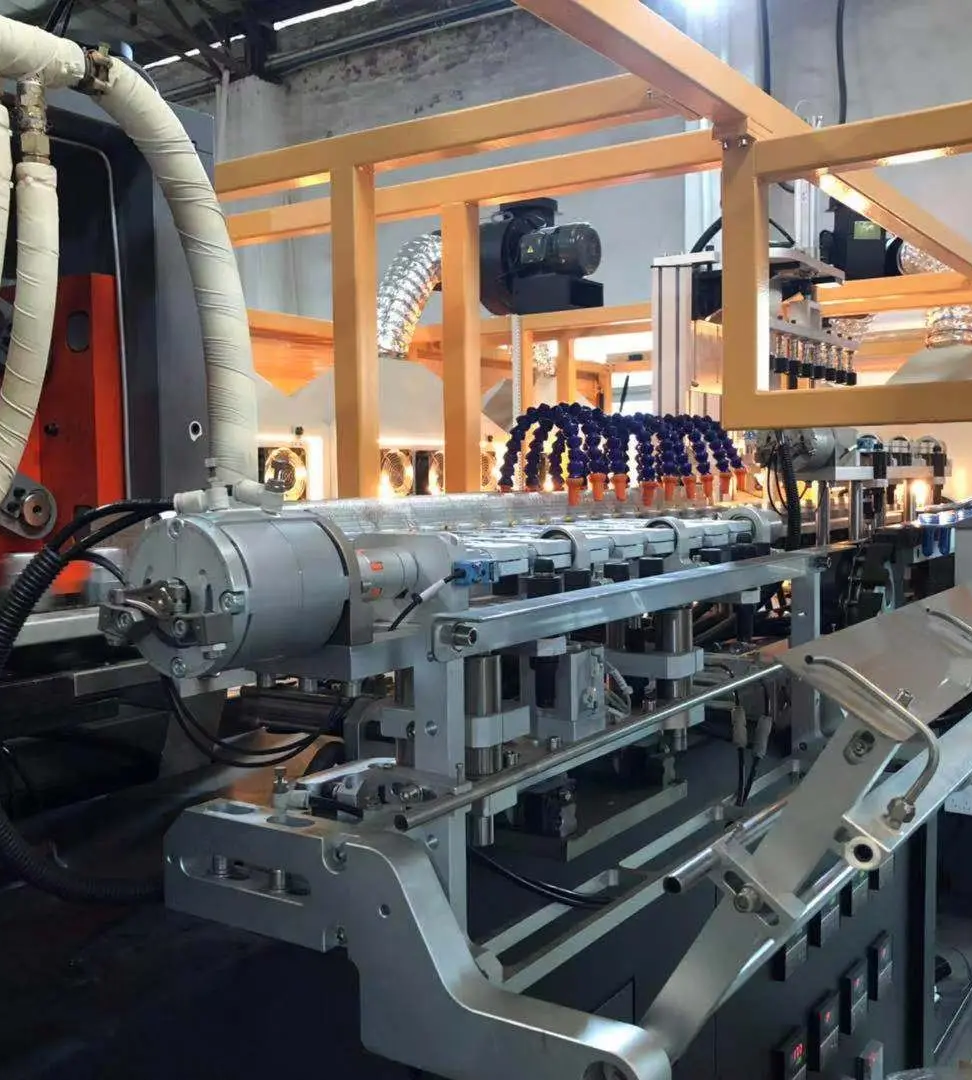

COMARK is a trendsetter regarding the use of new technology in the blow moulding market. Incorporation by COMARK of the newest technologies and control systems enables each production process to have the best features. Such machinery is developed in a manner that addresses various types of plastics, thus enabling the producers of bottles to have improved standards of production in terms of quality and strength. This is achieved because of the advanced programs available in COMARK machines, which makes it possible to control the entire molding process, temperature to air pressure Of course this means that manufacturers can rapidly respond to changes in bottle design and specifications without affecting turnover or quality. It is therefore no wonder that COMARK comes out as a favorable option for manufacturers who are in search of advanced and efficient production equipment.

Confidence is a foundation of blow molding machines produced by COMARK. These machines are made from strong materials and components that can last long under high-volume manufacturing conditions. Each machine is reliable and works consistently during tough times due to the thorough testing and quality control processes of this brand. As a result, reliability of this level prevents frequent breakdowns or repairs which may disrupt operations in enterprises thereby giving them peace of mind while ensuring smooth running as well.. When businesses select COMARK; they get much more than just another piece of equipment – what comes with it too is an investment into their future success since reliability such as this guarantees uninterrupted support towards achievement for many years ahead

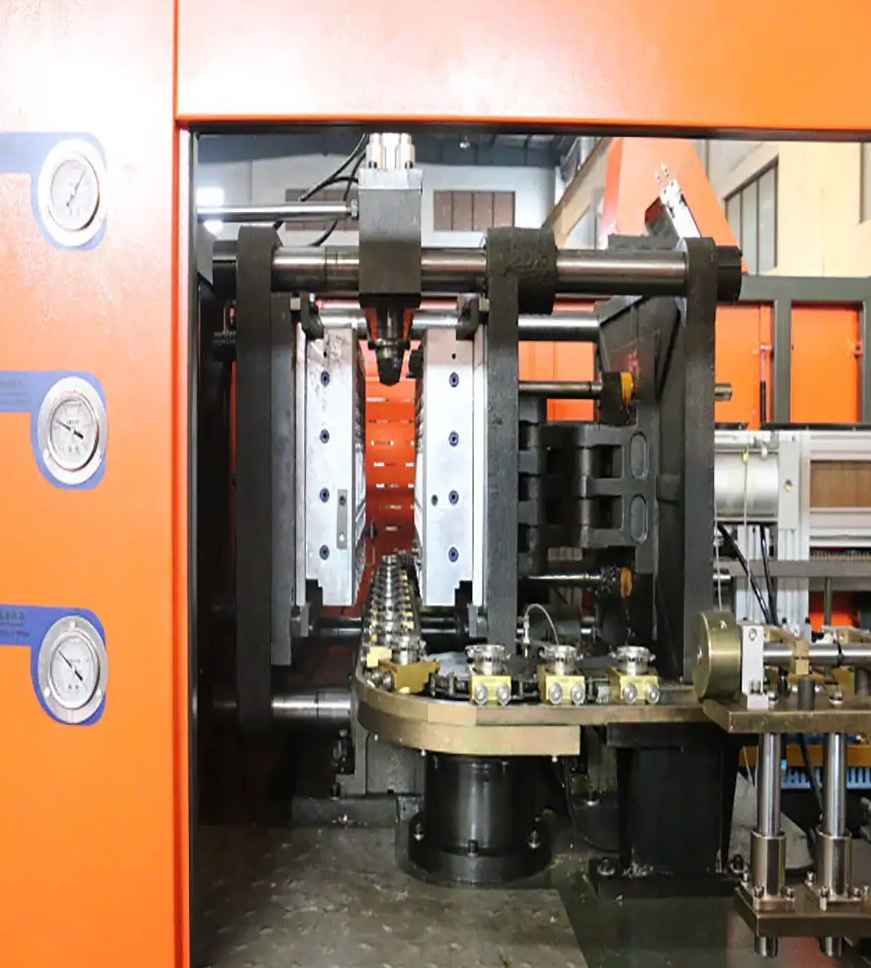

In every machine that it manufactures, COMARK is leading the way in innovation in the blow molding industry by using state-of-the-art technology. The COMARK Blow Molding Machine uses sophisticated automation and precision engineering to increase production speed as well as accuracy. With the incorporation of advanced molding systems, each COMARK machine guarantees top performance levels all through. This dedication towards progress through technology empowers enterprises to realize greater efficiency gains while cutting down on materials utilized for manufacturing at the same time achieving outstanding product quality standards. Whether one wants to enhance their current process efficiencies or scale up production volumes; no other player within this sector can match Comark's technological know-how.

Zhangjiagang COMARK Machinery Co Ltd has specialized in the export of beverage production line for 15 years. We specialize in providing customers with complete beverage(water, juice, carbonated soft drink, energy drink, ice tea and other) production turnkey projects for PET bottle,aluminium can, glass bottle.

We can provide following services:

1-all machines of complete production line

(water treatment system / mixing system / washing filling capping machine / laser code printer / labeling machine / packaging machine / bottle conveyor)

2-Provide raw material such as preform,cap,can, label, PE film and so on

3- About the machines installation, we have professional engineer who go to local, they will finished installation and train your engineer and workers

4-can design label, bottle shape and machines layout according your workshop

Comark Machinery leads beverage packaging R&D, delivering solutions. Dedication to upstream & downstream research ensures a full range.

Serving 30+ countries, Comark caters to industries like drinks, flavors, cosmetics, beer, milk, & pharma. Global reach & versatility strengthen their market position.

Comark focuses on tech innovation, filing patents & fostering a unique market position. This commitment keeps them ahead in beverage packaging.

Comark collaborates with top institutions to analyze & incorporate foreign tech, optimizing design & performance for remarkable improvements.

The COMARK Blow Moulding Machine is versatile and can produce a wide range of plastic products, including bottles, containers, and custom-shaped items. It is suitable for various types of thermoplastic materials, ensuring high-quality results for different applications.

The machine is equipped with advanced control systems and customizable settings that allow for precise adjustments. Its high-resolution sensors and automated controls ensure consistent moulding accuracy, reducing variability and maintaining product quality.

The production capacity varies depending on the model and configuration. Typically, the machine can handle high-volume production runs efficiently. For specific capacity details, please refer to the product specifications or contact our sales team for personalized information.

The machine features adjustable mould clamping and alignment systems that accommodate various mould sizes and shapes. This flexibility allows for easy transitions between different production runs and helps maintain high efficiency across different product lines.

Regular maintenance is essential to ensure optimal performance. This includes routine checks of the mechanical components, cleaning of the moulding areas, and periodic calibration of the control systems. The machine comes with a detailed maintenance guide and support from our technical team for any specific needs.