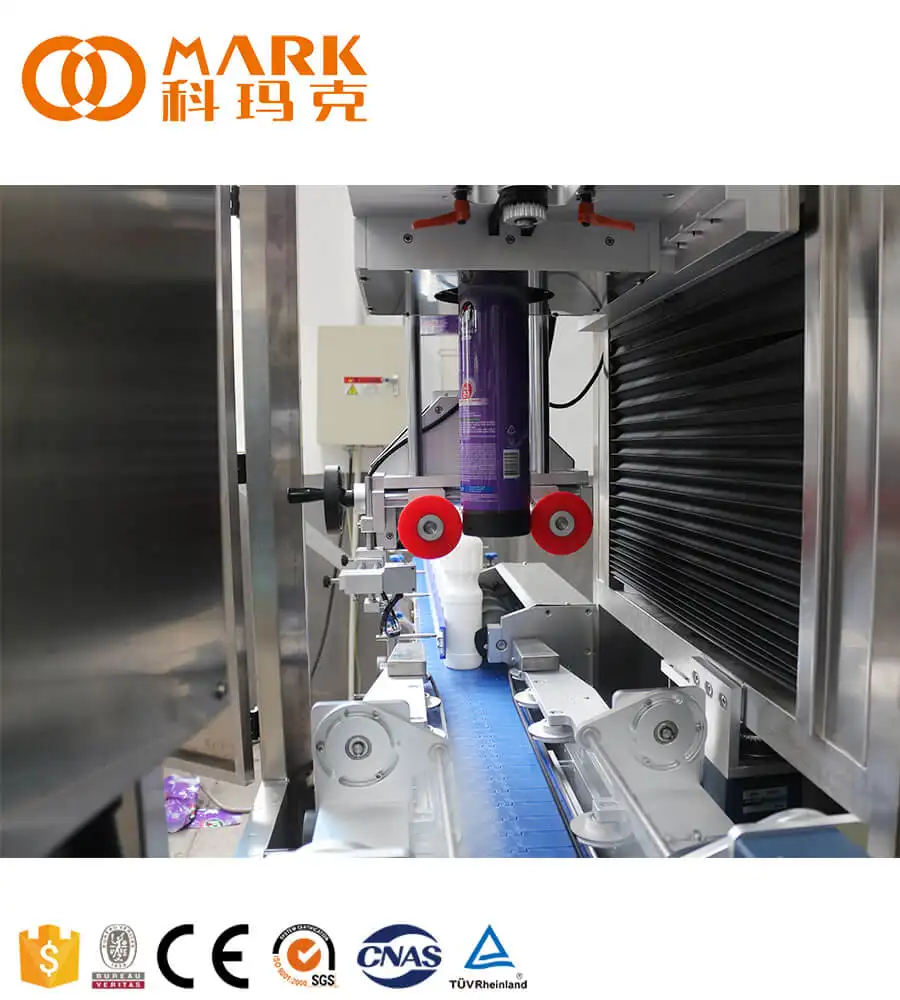

The COMARK Labeling Machine is engineered to provide exceptional precision and efficiency for all labeling needs. With its advanced technology, the COMARK machine ensures accurate placement of labels on a variety of containers and products. Its high-speed capabilities allow for rapid labeling without compromising quality, making it ideal for high-volume production lines. The machine's user-friendly interface simplifies operation and adjustments, while its durable construction guarantees reliable performance in demanding environments. The COMARK Labeling Machine's versatility and precision make it an essential tool for businesses aiming to enhance their packaging processes and maintain high standards of product presentation.

Ease of use and operational efficiency are the two main things that COMARK takes into consideration when designing their labeling machines. The COMARK Labeling Machine is equipped with a user-friendly interface for setting up, operating and adjusting it. This system has controls which can be easily understood by anyone operating it coupled with a clear display panel for showing various menus required during its operation thereby simplifying the work of the operator who may not be trained on how to use such machines.The design also allows for easy reach during maintenance therefore reducing downtimes that occur due to breakdowns while at the same time ensuring continuous running of operations.With this approach being centered around clients; businesses are able to streamline their processes involved in labeling thus improving general workflow efficiency.

The COMARK Labeling Machine is designed to cater to different packaging formats such as various can sizes and shapes thus making it versatile for use with different products. Its variability ensures that companies can cope with multiple production lines hence useful in adapting to evolving labeling needs within the industry. COMARK offers flexible labeling solutions suitable for any sector. This machine provides reliable and uniform results when used in labeling drinks, foodstuffs among other items.

The flexible design of COMARK’S labeling machines is one of the notable advantages of COMARK as such machines are meant to handle diverse labeling requirements. Be it a bottle that needs wrap-around labels or a cosmetic pack requiring front-and-back label or indeed a tamper-evident label for a pharmaceutical product – COMARK machines can cater for it all. Labels on our machines can be made of various sizes, types and placements and this is achieved in little time, which enables businesses to switch between different products within a limited timeframe. Machines produced by COMARK are well regarded for their new and effective design and are probably the most flexible, working with numerous adhesives and labeling materials as would be required by the manufacturer for any given production batch. PROVIDING MACHINES THAT ARE SOMETIMES COMPLEX AND YET RELIABLE HELPS COMARK’S CLIENTS IN MEETING GRIPPING MARKET DYNAMICS EVEN THOUGH MORE COMPLEX LABELING STRATEGIES ARE UTILIZED.

In the packaging world, COMARK is a leader in label technology and offers new solutions. In order to improve precision and speed of labeling procedures, it was equipped with advanced sensors and automated controls that guarantee correct positioning of labels every time. To reduce mistake rates and enhance general product appearance this device may accommodate various sizes and types of labels. This makes it suitable for different uses since versatility is added by being able to work with many kinds of tags as well as their sizes too.The main goal behind all these features implemented by COMARK into their Labeling Machine was always innovation – achievement better results than any other business in the market can do so while staying competitive

Zhangjiagang COMARK Machinery Co Ltd has specialized in the export of beverage production line for 15 years. We specialize in providing customers with complete beverage(water, juice, carbonated soft drink, energy drink, ice tea and other) production turnkey projects for PET bottle,aluminium can, glass bottle.

We can provide following services:

1-all machines of complete production line

(water treatment system / mixing system / washing filling capping machine / laser code printer / labeling machine / packaging machine / bottle conveyor)

2-Provide raw material such as preform,cap,can, label, PE film and so on

3- About the machines installation, we have professional engineer who go to local, they will finished installation and train your engineer and workers

4-can design label, bottle shape and machines layout according your workshop

Comark Machinery leads beverage packaging R&D, delivering solutions. Dedication to upstream & downstream research ensures a full range.

Serving 30+ countries, Comark caters to industries like drinks, flavors, cosmetics, beer, milk, & pharma. Global reach & versatility strengthen their market position.

Comark focuses on tech innovation, filing patents & fostering a unique market position. This commitment keeps them ahead in beverage packaging.

Comark collaborates with top institutions to analyze & incorporate foreign tech, optimizing design & performance for remarkable improvements.

The COMARK Labeling Machine is versatile and can handle a wide range of products, including bottles, jars, cans, and other containers. It is designed to apply labels to various shapes and sizes with precision.

The machine uses advanced alignment systems and sensors to ensure accurate label placement. Its precise controls and adjustable settings allow for consistent application, reducing errors and ensuring high-quality results.

The labeling speed varies depending on the model and configuration of the machine. Generally, it can handle high-speed production runs efficiently. For specific speed capabilities, please refer to the product specifications or contact our sales team.

Yes, the machine is designed to accommodate various label sizes and types. It features adjustable settings and interchangeable parts that allow for easy changes between different label formats and container dimensions.

Regular maintenance includes routine checks of the mechanical components, cleaning of the labeling areas, and calibration of the alignment and dispensing systems. The machine comes with a detailed maintenance guide, and our technical support team is available for additional assistance.