Whole 5 Gallon Pure Drinking Water Bottling Production Line

Description

Whole 5 Gallon Pure Drinking Water Bottling Production Line

Barreled water production line is specially used for the production of 3 gallon, 5 gallon barreled drinking water.The machine integrates washing, filling and capping functions.It is an ideal equipment for mineral water, distilled water and purified water production.The machine adopts high quality stainless steel, corrosion resistance, easy to clean.The main electrical components are SIEMENS and OMRON products.Airway system adopts imported AIRTAC famous brand products.The machine has the advantages of compact structure, small workshop area, high efficiency, stable and reliable, and high degree of automation.Operators only need two people, is a trinity of mechanical and electrical automatic barrel equipment.

Technical Parameters

|

Model |

QGF-150 |

QGF-300 |

QGF-450 |

QGF-600 |

QGF-900 |

QGF-1200 |

|

Capacity(BPH) |

150 |

300 |

450 |

600 |

900 |

1200 |

|

Filling heads |

1 |

2 |

3 |

4 |

5 |

6 |

|

Power supply(kw) |

1.38 |

3.8 |

5.6 |

7.5 |

9.75 |

12 |

|

Size(mm) |

3700*1300*1600 |

4060*1860*1600 |

5000*2600*2200 |

5400*2600*2200 |

8500*6000*2500 |

9000*6500*2800 |

|

Weight(kG) |

680 |

1500 |

2100 |

3000 |

3500 |

4000 |

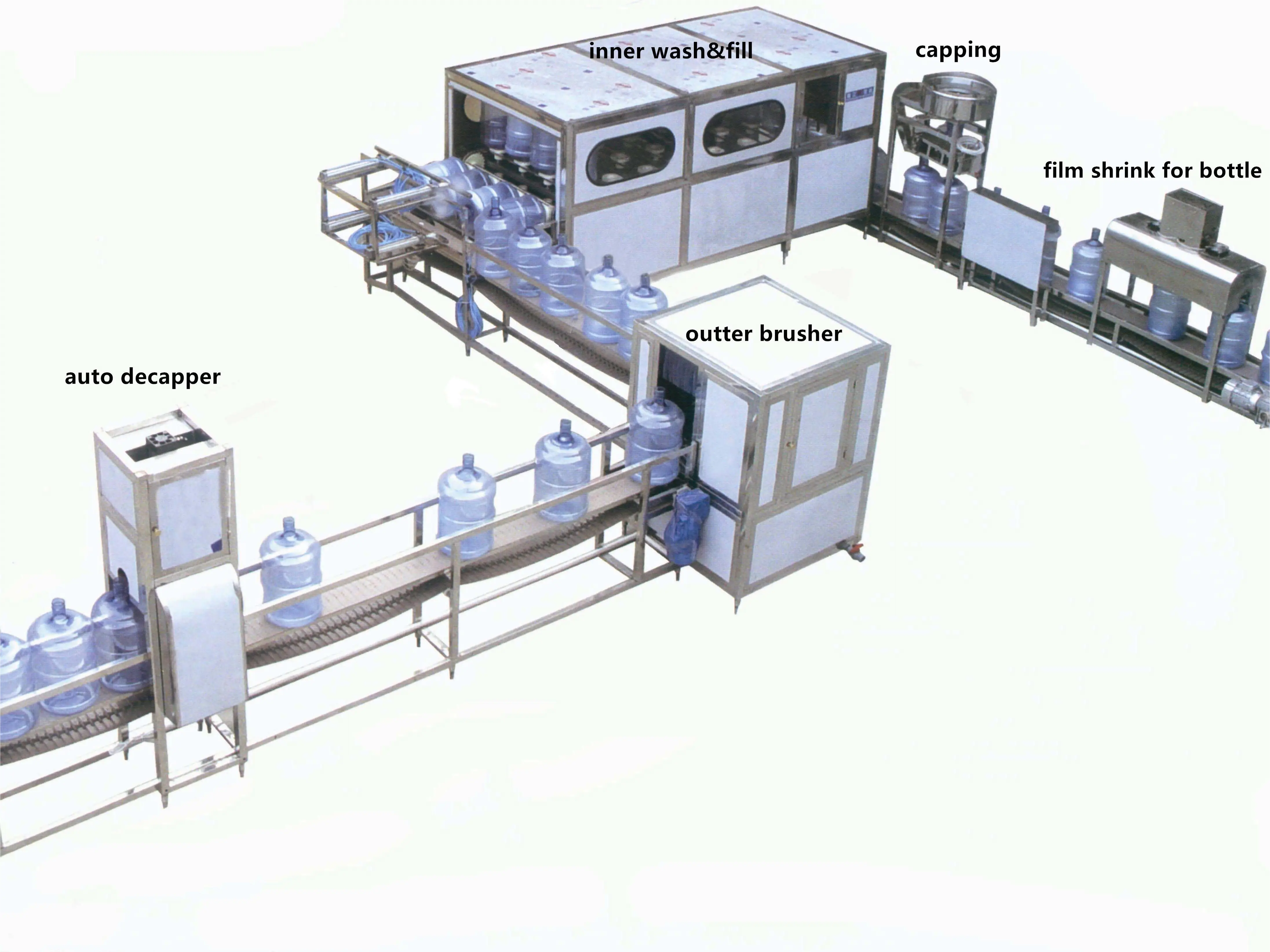

The complete production line includes:

▶ 3-5 Gallon PET bottle blow molding machine

▶ Water treatment system

▶ Automatic de-capping machine

▶ Barrel external brushing

▶ 5 Gallon Water Filling Machine

▶ Automatic barrel Neck Labeling Machine

▶ PE Film Wrapping Machine

▶ Automatic palletizer

3-5 Gallon PET Bottle Blow Molding Machine

1. Blow moulding machine 100-250bph, and 3-5Gallon PET bottles are available.

2. It is used to produce the 3-5 gallon water barrel.

3. The man-machine interface is highly automated and easy to operate.

Water Treatment System

It is mainly composed of the following equipments:

1. Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter)

2. Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system)

3. Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on.4> Used for pure water, mineral water and other bottled water,water for food and beverage production.

Automatic De-capping Machine

Automatic cap remover machine is used to remove 5 gallon bottle cap ,easy operation and maintenance.

1) Simple structure in linear type ,easy in installation and maintenance.

2) SUS stainless steel 304 material frame.

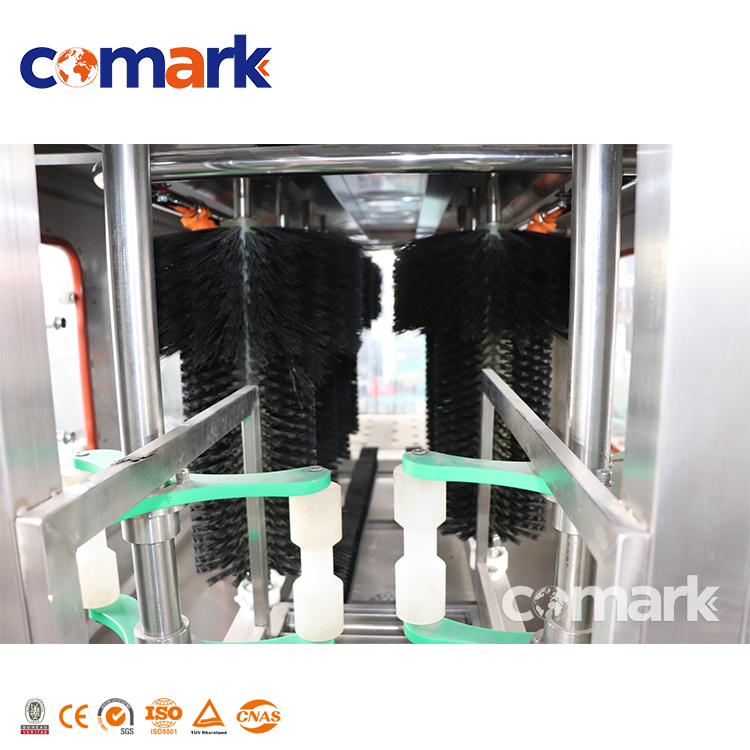

Barrel External Brushing

Automatic barrel outer brushing machine specially work with 5 Gallon barreled water producing line. It is used for reducing the settling caused by the mineral water itself and some algae substances in the process of mineral water producing. The machine is made of excellent stainless steel with the advantage of easily-rinsing and corruption-resistance.

5 Gallon Water Filling Machine

1. Water filling machine is used for barrel water, 3-5 Gallon barrel PET/PC bottles are available.

2. Water filling line can apply to fill natural spring water, purified water into PET bottle by changing few spare parts.

3. Automatic water filling machine adopts rinsing, filling and capping 3-in-1 technology, PLC control, touch screen. It is mainly made of SUS304/ SUS316.

4. The whole production filling line accuracy is more or less than 1%.

Automatic Barrel Neck Labeling Machine

The shrinking machine is equipped with an adjustable temperature controller, which has uniform heat shrinkage, stable operation and low failure rate.The matching conveyor chain of the heat shrinking machine can adjust the linear speed steplessly or adapt to different speeds to achieve the best heat shrinking effect.

PE Film Wrapping Machine

1. Compact &artistic shape. The frame is novel, unique.

2. Electronic induction feeding film, action is balanced and quickly replacing film.

3. Isothermal sealing cutter .The seal intensity is above cooling sealing cutter 3 times, the seal is even and the life is above cooling sealing cutter 80 times.

Automatic Palletizer

According to a certain order, palletizer stacks the packed products(in box, bag, bucket) to the corresponding empty pallets through a series of mechanical actions so as to facilitate handling and transporting batches of products to improve production efficiency. Meanwhile it can use stack layer pad to improve the stability of each stack layer. Various forms designed to meet different palletizing requirements.

FAQ

Q:If we purchase machines, what can you provide for us?

A1:We can provide whole solutions.We have professional engineer who analysis production demand based on customer market demand and customer budget .

A2:We have the bottle shape design according to customer inquire. We also can provide the machines layout for you according your factory figure plan.

A3:We will send our professional engineer to your factory as soon as you get all your machines ready, for installation, testing and teaching your technicians how to run the machines.