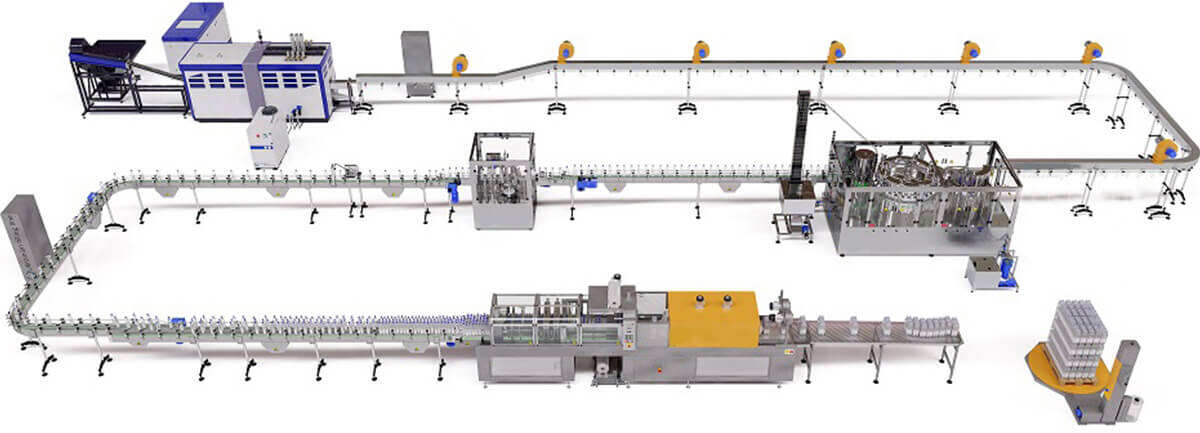

2000BPH Automatic Juice Glass Bottle Filling Package

Description

The series equipment is used for glass bottle rinsing/ filling/ sealing 3-in-1 unit machine for water/ juice/ tea/ wine and so on.And the capping part can be manufactured with crown cap/ screw cap/ normal cap.The machine integrates washing, filling, capping together. The design is scientific and reasonable. Its appearance is beautiful.Its operation and maintenance is convenient. The automation is high. It is good equipment for choosing hot drink filling machine. This series machine is adopt block bottle-neck hanging work state design, and be adopt filling valve rise-drop design, It's be satisfy for 95 degree hereinafter hot filling technology demand. It's adopted person-machine interface touch-screen, PLC, transducer etc advanced control technology. It's osculate the drink material parts are adopt the SUS304 stainless steel, The machine main motor, reducer, mostly axletree, pressurize parts and electricity ware element, gas drive element etc are adopt famous international manufacturer products.

5000BPH Automatic Juice Glass Bottle Filling Package

This machine has washer,filler,capper three functions in one body, it is automatic in total process and suitable for PET bottled water without gas.The total machine uses advanced photoelectric detection technology to detect each parts operation status, no bottle no filling, and no bottle no capping, automatic and easy operation.

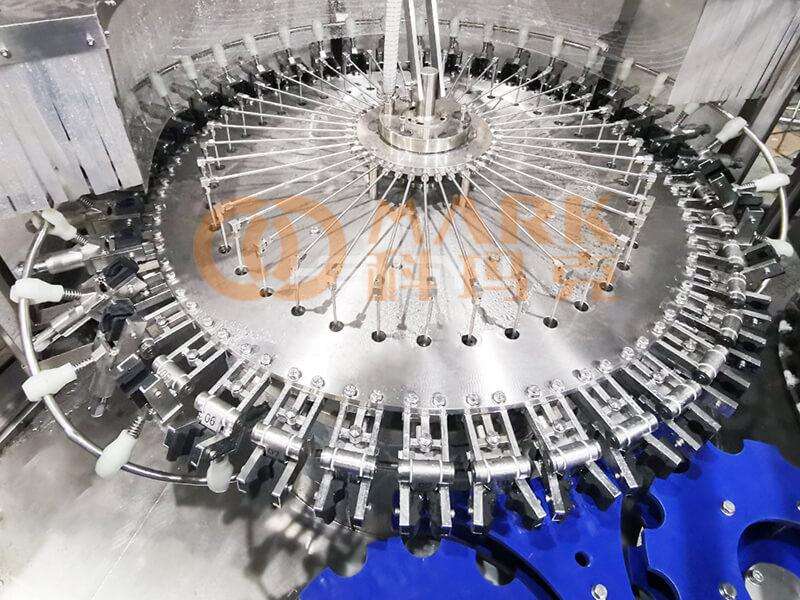

Washing heads

The most advanced technology is employed in the design.The gravity fixed liquid surface filling is used. The filling is fast,the amount of liquid is accurately controlled and the dropping and leakage are avoided.

Filling heads

Spring cramps are used in the bottle washing process.The empty bottles can be turned over 180* along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Capping heads

The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged,the capping is reliable.

Technical Parameters

|

Model(BCGF) |

14/12/5 |

18/18/6 |

24/24/6 |

32/32/8 |

40/40/12 |

50/50/12 |

60/60/15 |

|

Washing heads |

14 |

18 |

24 |

32 |

40 |

50 |

60 |

|

Filling heads |

12 |

18 |

24 |

32 |

40 |

50 |

60 |

|

Cappping heads |

5 |

6 |

6 |

8 |

12 |

12 |

15 |

|

Capacity(BPH) |

2000 |

3500 |

5000 |

8000 |

12000 |

16000 |

20000 |

|

Power(kw) |

2.2 |

3.5 |

4.5 |

6 |

7.5 |

9.5 |

11.2 |

|

Dimension(mm) |

2400*1600*2500 |

2600*1920*2550 |

3100*2300*2800 |

3800*2500*2900 |

4600*280082900 |

5450*3300*2900 |

6500*4500*2900 |

|

Weight(kg) |

2500 |

3500 |

4500 |

5600 |

8500 |

9800 |

12800 |

Main Features

1. Touch screen operation interface.

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

3. The filling accuracy can reach ±0.2%.

4. With no bottle no flling and automatic bottle stop function.

5. Design different positioning devices according to the actual situation of the bottle.

6. PLC programmable control use Japan Mitsubishi.

7. Material contact parts are made of SUS304# stainless steel.

Whole Line Device

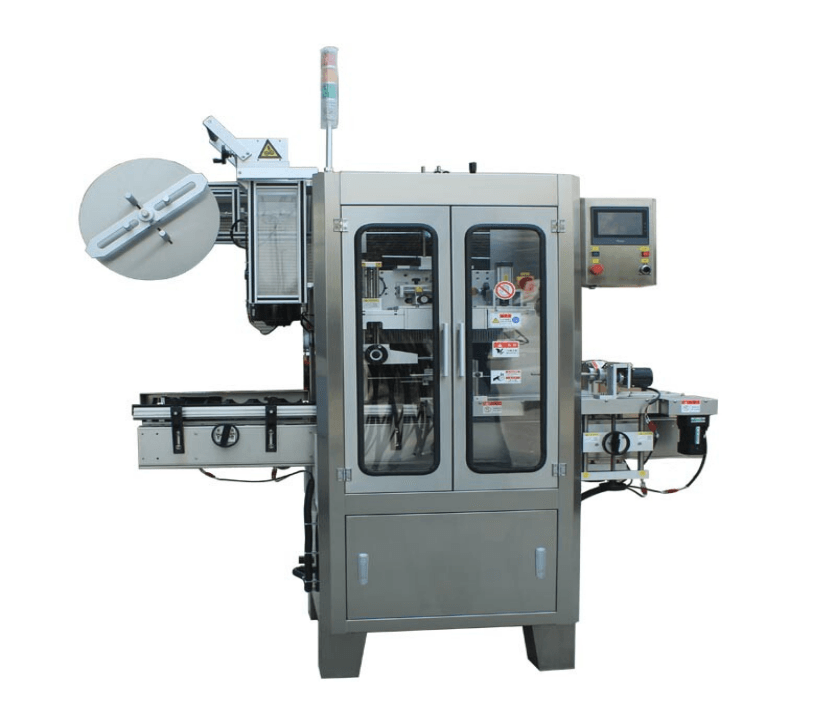

PVC Shrink Sleeve Labeling Machine

The machine can be used for various bottle types, such as: round bottle, square bottle, flat bottle, curve bottle, cup, and so on. Labeling machine is controlled by PLC touch screen, all-electric eyes are using imported advanced configuration. High speed, high accuracy, stable performance.

Automatic PE Film Shrink Wrapping Machine

(1)350/500/550/600ML

large package: 4*6, 4*5

Small package: 3*4, 3*5

(2)1L/1.5L/2L/2.5L

large package:3*3,3*4 Small Package:2*2,2*3beverage machinery

High efficiency and stability, simple operation.

PLC control, quality assurance.