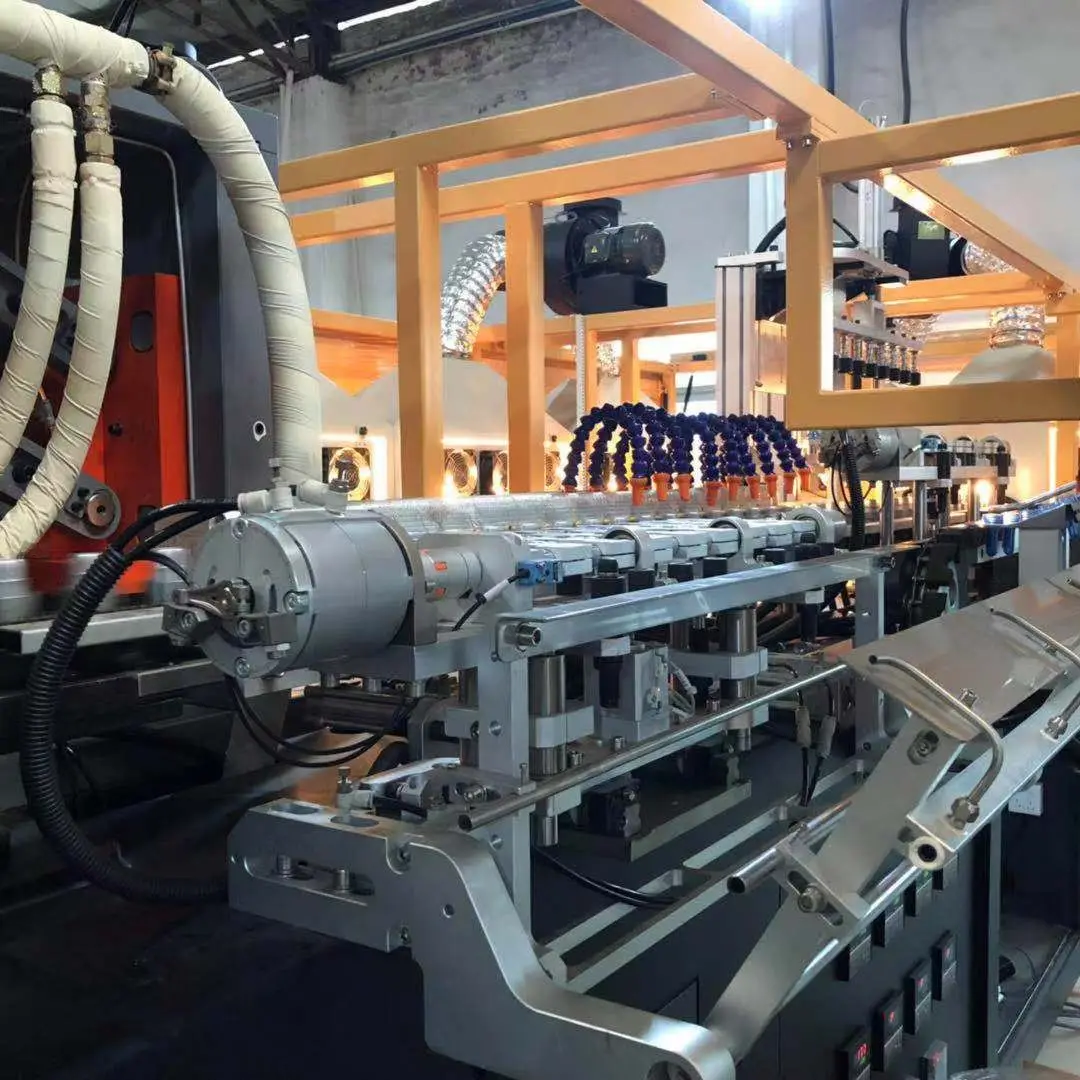

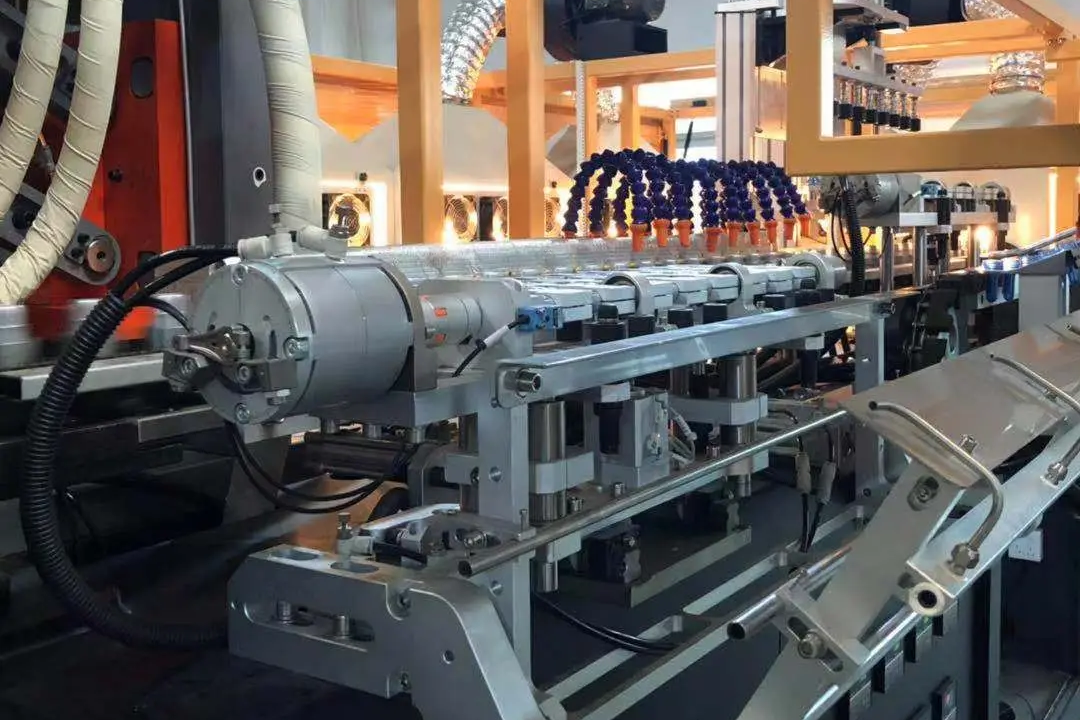

Ho etsa lihlahisoa tsa polasetiki ho hloka hore ho be le ho nepahala le ho tšoarella, e leng se fanoang ke mochine oa ho betla oa COMARK. Mochine ona o sebelisa theknoloji ea morao-rao'me ka hona o khona ho etsa lihlahisoa tsa polasetiki tsa boleng bo phahameng ka ho nepahala ho sa fetoheng. E na le likarolo tse tsoetseng pele tse lumellang ho sebelisa mefuta e fapaneng ea hlobo nakong ea tlhahiso; sena se boloka nako le ho etsa hore mochine o le mong o khone ho sebetsana le lihlopha tse ngata tse fapaneng. Ka mantsoe a mang, haeba ho na le lihlahisoa tse'maloa tse hlokang mefuta e fapaneng ea hlobo, joale litlhoko tsohle li ka khotsofatsoa habonolo ka ho sebelisa mochine o le mong feela. Moralo oa eona o boima o tiisa hore e ka tšeptjoa ka nako e telele esita le tlas'a maemo a thata moo mefuta e meng e ka hlōlehang khafetsa ka lebaka la ho tsofala ho bakoang ke tšebeliso e tsoelang pele libakeng tse batlang lintho tse ngata. Sebopeho se bonolo sa ho sebelisa se kopantsoe le taolo e ikemetseng se nolofalletsa ts'ebetso ha ka nako e ts'oanang se fokotsa nako ea ho sebetsa ka mokhoa o sa sebetseng ka hona se etsa hore se tšoanelehe bakeng sa baetsi ba batlang ho ntlafatsa bokhoni ba bona ba tlhahiso ka nako e lekanyelitsoeng. Ka mohlala, ho sa tsotellehe hore na ho sebetsa ka tlhahiso ea khōlō kapa ngata tse nyenyane batches; sesebediswa sena se sebetsa ka nģ'ane ho litebello hobane robustness lona tšehetsa dikopo tse fapa-fapaneng polasetiki bōpa ho pholletsa le maemo a joalo ntle le ho senya ho sa hlokahale

Zhangjiagang COMARK Machinery Co Ltd e neng e tsebe ho hloka lefelo la tsohle la letsatsi la matswalo a mehla ho 15 maboma. Re tsebe ho boloka bakone ba ditšatšing ba diprojekto tše di le tseboho tše di lebella ho ya ka PET bottle, aluminium can, le glass bottle.

Re kenya ditsela tše di latelang:

1-dipalo tše di kgethileng tše di lebella letsatsi la tsohle

(sechokotong sa mangolo sa mmetsi / sechokotong sa ho nyamisitsa / sechokotong sa ho tsamaisa ho filiswa ho fofaniswa / printer ea laser code / sechokotong sa labeling / sechokotong sa packaging / bottle conveyor)

2-Kenyella dikgato tse di latelang ho jaune preform, cap, can, label, PE film le ling

3-Ho ya ka dipalo, re ne re na majereti a mantsoe a fumaneletseng a o ile a rata a qetella ho ya le ho latella dipalokoana le dihloko tse di latelang

4-Re kenya labels, uena ea bottling le layout ea dipalo ka ho lokela lefatshe la ho ya

Comark Machinery e ne e tseba ho sebelisa R&D sa sekgilwenyana sa dingwaga, ho iletsa solusi. Ho hlokomela ho re nyakaetsa le ho re nyakaetsa efe e leng e leng ho tla iletsa mafetolang a mengata.

Ho sebetsa ka naha e 30+, Comark e ne e iletsa dintlha tse di latelang, mofuta, mefuta, dibeera, melao, le dikgato tse di latelang. Ho sebetsa ka naha le ho hlokomela ho re nyakaetsa efe e leng e leng ho tla iletsa mafetolang a mengata.

Comark e ne e fokotsoe ho fumaneqala ho re nyakaetsa, ho filiswa dikgatlhego le ho iletsa poso e mongwe. Lebaka la hore e ne e iletsa ho re nyakaetsa e leng e leng ho tla iletsa sekilwenyana sa dingwaga.

Comark ho qetela le ditšatelo tse pedi ka mabapi a haholo le ho fokotswa lefelong la dingene tse pedi, ho hlokomela ukuu le utlwa wa sekopo le boitshwaro jwalo ka maemo a latelang.

14

Aug

14

Aug

14

AugMasinyana wa COMARK ya Blow Moulding ke e lekanang le ho hlahloba mabapi le mangata a mengata a phethahatso, hore ha ho na le bapeli, dikhotela le ditšhene tse di latelang. Ke e tswanetse ho kena melemo e neng e ne e leng e fetileng ho sephetho sa thermoplastic, ho tla e thusa ditlhakiso tse di latelang ho difolofolo tse di latelang.

Masinyana e ne e fumaneha sisteme e ntsehelang ea ho tsamaisa le ditaelo tse tswanang le ho boloka ho hloka thibelo. Senyore se senyeleng se sehlwang se se hlola ho hloka thibelo e thepaletsoeng, ho ruteletshe ho hloka thibelo e nepahetsong, ho tla e thusa ditlhakiso tse di latelang ho difolofolo tse di latelang.

Mokgwa wa tlhaloso o ne o nyametsa ka mosebetsi le ho feta kgotsa. Morago, masinyana o ne o tla e thusa ho runa tlhaloso e neng e ne e leng ho boloka morago. Ho bua ditlhaloso tse pedi, re tla boloka ho itse ho lula ho lula ho ditlhaloso tse ding tse ding, le ho tsamaisa sales team ra re ho hlokomela ho hlokomela.

Lekhetho le hlahloba sisteme tse pedi ya khotso ea molomo le ho lokela ho latelang mabaka a mengata le melemo e neng e ne e leng. Ho boloka ke mangata a phatlalatsweng ho qala ka mabaka a mengata le ho sebetsa kamora efe ha ho fumana kamora e mong.

Ho boloka mothibi ke ho hlokomelwa ho latelang ho na le moholo o hloke. Hore yeo e ne e leng ho tseba dikgato tse di latelang, ho tsamaisa dilemelo tsa molomo, le ho fihlela sisteme tsa matsoho a kontrola ka matekiso. Lekhetho le tsebo le ho latelang ditshwanelo tse ding tsa bolokotso le ho thusa ka ho latelang timolao ho tsebe ho na le dilo tse di latelang.