Carbonated Metsi Beverage Tlatsa Bottling Tlatsa Capping Production Line

Simple Sebelisa Reliable jarolla ka ho iketsa Bottle Carbonated Soft Seno tlatsa Machine Production Line

Sena DCGF Hlatsoa-tlatsa-capping 3-in-1 unit: Beverage mechine e sebediswa ho hlahisa poliester bottled lino tse bonolo, soda seno, le tse ling k'habone ...

Tlhaloso ea tlhaloso

Simple Sebelisa Reliable jarolla ka ho iketsa Bottle Carbonated Soft Seno tlatsa Machine Production Line

Sena DCGF Hlatsoa-tlatsa-capping 3-in-1 unit: Beverage mechine e sebediswa ho hlahisa poliester bottled lino tse bonolo, seno soda, le tse ling tse carbonated tsoakane lino tse tahang mechine. THE DCGF Hlatsoa-tlatsa-capping 3-in-1 unit: Beverage mechine ka qeta tshebetso tsohle tse kang tobetsa botlolo, tlatsa le ho tiisa, e ka fokotsa thepa le ka ntle ho thetsana nako, ntlafatsa maemo bohloeki, bokgoni tlhahiso le bokgoni moruo.

The ho fanyeha botlolo-molaleng conveyor sebopeho etsa libotlolo stably nakong maemo a phahameng a tsamaeang, 'me a etsa phetoho botlolo ea mohlala loketseng haholoanyane. Human mochine segokanyimmediamentsi sa sebolokigolo thetsana-skrine le PLC lenaneo etsa hore e tekanyo e phahameng ea tlhahiso jarolla ka ho iketsa. Likarolo tsohle tse kopaneng ka kotloloho le metsi li entsoe ka tšepe ea boleng bo holimo e sa hloekang. Likarolo tsa mantlha tsa motlakase li tsoa lik'hamphaning tse tummeng tsa machabeng, joalo ka Mitsubishi Schneider, Omron.

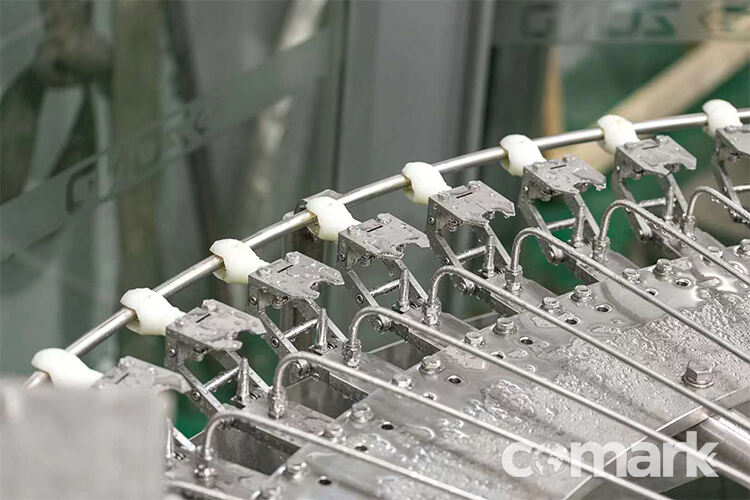

1. the oa rotary lebili ke ka botlalo celik welded sebopeho.

2. lihlahla tsohle sliding tsa ho phahamisa sesebediswa sebelisa Igus (Jeremane)-ba khahlanong le ts'enyeho tlhokomelo mahala behang.

3. the rinser e khannoang ke tsamaiso khanna boemong ba ka hare mochini foreime ka phetiso Gear.

Mochini o sebetsa o ikhethileng oa ho phethola botlolo ea botlolo, e leng boqapi ba k'hamphani ea rona. Botlolo ena clamp grips botlolo molaleng, qoba botlolo molomo molomo silafatsoa bakoang ke rabara gripper block tsa setso botlolo clamp. E entsoe ka SUS304 stainless steel, clamp ena ea botlolo e hloekile ebile e tšoarella.

5. phahameng bokgoni atomizing spay nozzle hlomamisa ka botlolo clamp ke khona ho hloekisa karolo efe kapa efe ea botlolo leboteng ka hare,' me hape boloka rinsing metsi.

1.Rotary lebili ka botlalo entsoe ka celik SUS 304.

2.2 Li-valve tsa ho tlatsa li entsoe ka SUS316L.

3. ho tlatsa li-valve li hlophisitsoe ka mokhoa o utloahalang ka ho tlatsa ka nepo.

4. libotlolo nyoloha 'me theoha mosebetsing oa Cam pholletsa lifte, ho sebetsana le ho tlatsa ka ikopanya le botlolo-molomo.

5.Cylinder e laoloa ka float-ball.

6.Filler e khannoa ka li-gear kahare ho foreimi ea mochini.

7. link-mabili ka rinser, filler le capper ba tsamaisoa ka tšehetso ringed tsa botlolo-molaleng.

1. Phahameng lebelo le phahameng sebetsa ka ho nepahetseng capping thekenoloji le etsa bonnete ba capping tlase ≤0.2%.

2. capping moea tightness ≥ 99.99%

3.Adopted ka theknoloji e sa khaotseng magnetic torque capping. Phello ea capping e tsitsitse ebile e ts'epahala.

Mochini oa blow moulding 1,000-24,000bph, le 0.2-2L / 3-5L libotlolo tsa PET lia fumaneha.

2. E sebelisoa haholo ho hlahisa botlolo ea carbonated, metsi a diminerale, litlolo tsa botlolo ea botlolo ea oli e bolaeang likokoana-hloko, botlolo ea molomo o sephara le botlolo e chesang ea ho tlatsa, jj.

3. the man-mochine segokanyimmediamentsi sa sebolokigolo ke haholo jarolla ka ho iketsa le ho le bonolo ho sebetsa.

4. mochini o kopaneng o lula sebakeng se senyenyane.

1.The beverage processing system e sebetsa ho nooang production line

2. sehlahisoa oona tsamaisong metsi a chesang, tsamaiso e khopo e qhibilihisa tsoekere (tsamaiso e bonolo sirapo), concentrateing tsamaiso e khopo, tsoarellang tsamaiso (tsamaiso ea ho qetela sirapo), CIP tsamaiso, tsamaiso ea ho ntsha, mofuta oa polokelo / di-valve / phala / fittings, UHT tsamaiso (poleiti / tubular mofuta), le carbo-cooler / mixer (pukwanana / jarolla ka ho iketsa).

1. pre-kalafo tsamaiso (tanka metsi / multi-mahareng filtara / sebetsang k'habone filtara / Ion exchanger / bohlokoa filtara)

2. membrane oona tsamaisong karohano (ultrafilter / nanometer filtara / RO reverse osmosis tsamaiso)

3. electrodialysis sesebelisoa / tanka ea metsi ea sehlahisoa joalo-joalo.

Mochini o ka sebelisoa bakeng sa mefuta e fapaneng ea botlolo, joalo ka: botlolo e chitja, botlolo e bataletseng, joalo-joalo.

2. Labeling mochine e laoloa ke PLC thetsana skrine, tsohle-motlakase mahlo a sebelisa imported e tsoetseng pele phetolo.

3. Lebelo le phahameng, ho nepahala ho phahameng, ts'ebetso e tsitsitseng.

1. PE filimi shrink wrapping mochini ke a loketse bakeng sa wrapping lihlahisoa tse kang metsi a diminerale, libotlolo biri, lino joalo-joalo ntle tlase-terei (kapa ka tlase-terei).

2. sebetsa le PE shrink kotopo ho paka thepa ka ho phethahetseng. Ts'ebetso eohle ea tlhahiso e amohela Jeremane technics e tsoetseng pele.