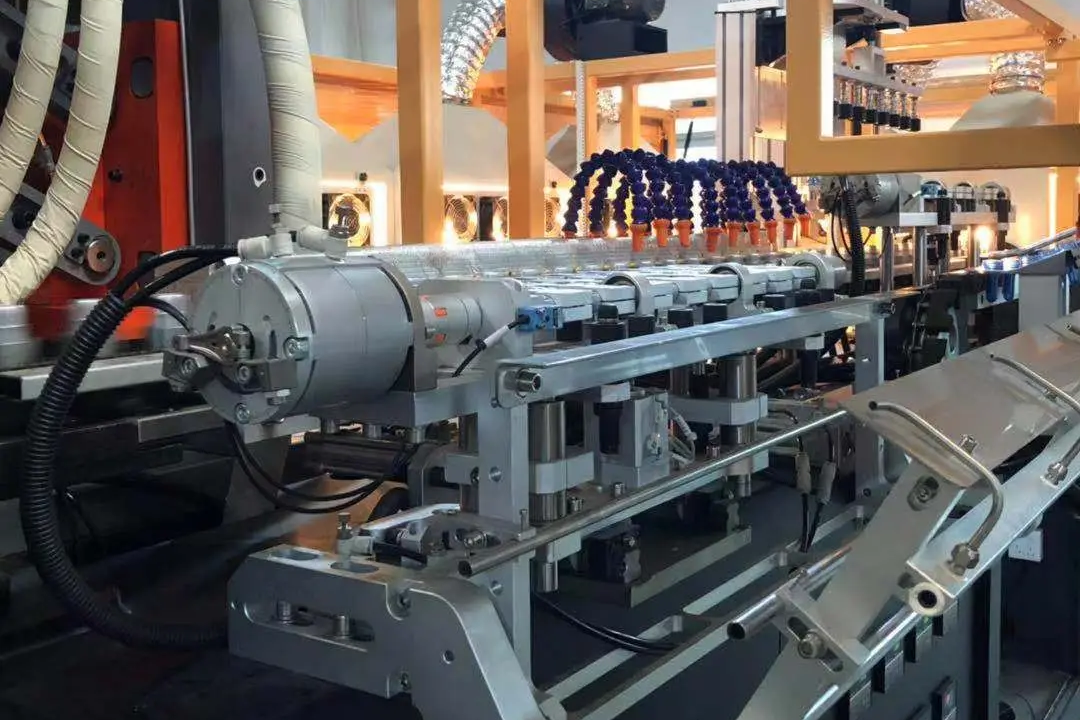

Masa de umplere a apelor COMARK este proiectată pentru a oferi rezultate cu performanță ridicată și o precizie fără egal. Dispozitivul include un mecanism avansat de umplere care poate să-acomodeze diferite dimensiuni și tipuri de sticle, făcându-l versatil pentru diferite nevoi de umplere a sticlelor cu apă. Operațiunea rapidă a mașinii și umplerea precisă asigură că obiectivele de producție sunt îndeplinite eficient. Angajamentul COMARK față de calitate se reflectă în designul durabil al mașinii, care sprijină operațiuni pe termen lung cu o întreținere minimă. Cu fiabilitatea sa excepțională și interfața prietenoasă utilizatorului, Masa de Umplere a Apelor COMARK oferă o soluție optimă pentru afacerile care doresc să-și îmbunătățească procesele de umplere a apelor și să atingă o ieșire consistentă și de înaltă calitate.

Echipamentul de umplere cu apă al COMARK este cunoscut pentru precizie. Mașina de umplere cu apă COMARK este construită pentru a oferi o acuratețe fără precedent în fiecare umplere. Dispozitivul poate detecta chiar cele mai mici abateri față de calibrarea setată, folosind senzori avansați și tehnologie de calibrare, asigurând astfel că toate sticlele sunt umplute cu cantitatea exactă de lichid necesară, ceea ce reducere pierderile și îmbunătățește uniformitatea printre produse. Acest nivel de precizie ajută să se evite situații în care recipientele ar putea fi umplute prea puțin sau prea mult, ceea ce joacă un rol esențial în menținerea controlului stricte al calității. În efortul de a atinge niveluri excepționale de precizie, COMARK oferă afacerilor soluții de încredere care optimiză eficiența și îmbunătățesc acuratețea în timpul proceselor lor de embalare a apei.

Caracteristicile avansate și capacitățile mașinilor de umplere cu apă produse de COMARK sunt dovada angajamentului companiei față de inovare. Printre cele mai recente progrese în tehnologia de umplere se numără Mașina de Umplere cu Apă COMARK, care vine cu controale precise precum și sisteme autoregulatoare care sporesc eficiența în ansamblu. Ca parte a eforturilor de a îmbunătăți echipamentele în timp ce păstrează ritmul schimbărilor din acest sector, COMARK investește mereu mult în cercetare și dezvoltare. Asemenea dedicație față de noutate înseamnă că ei nu furnizează doar ceea ce este necesar piețelor actuale, ci și așteptările viitoare, oferind astfel întreprinderilor soluții inovatoare care stimulează creșterea.

Pentru a garanta o calitate ridicată, performanță și fiabilitate, COMARK integrează tehnologie modernă în mașinile sale de umplere cu apă. Mașina utilizează mecanisme inovatoare de umplere care produc rezultate consistente pentru diferite dimensiuni și tipuri de sticle. Senzorii săi avansați și controalele automate îmbunătățesc precizia, reducând erorile și pierderile. Prin utilizarea celor mai recente progrese tehnologice, COMARK se asigură că mașinile lor de umplere cu apă sunt mai eficiente decât oricare alte, permițând afacerilor să optimizeze procesele lor de producție, menținând la fel standardele de calitate.

Modul în care COMARK a arătat angajamentul său față de durabilitate în construirea mașinilor de umplere cu apă este prin proiectarea și constructia lor. Mașina de Umplere cu Apă COMARK este fabricată din materiale de înaltă calitate, cu elemente puternice care garantează performanța acesteia pe perioade lungi, chiar și în condiții dificile. De exemplu, are o cadră robustă care poate funcționa în mod continuu fără a se strica des, ceea ce reducă timpul necesar pentru reparații și întreținere, deoarece sunt concepute folosind piese rezistente la uzură. Această atenție acordată solidității duce la mai puține oprirea și un output mai mare, devenind astfel o alegere excelentă pentru companiile care caută sisteme de umplere de încredere pe termen lung, conform nevoilor.

Zhangjiagang COMARK Machinery Co Ltd s-a specializat în exportul liniei de producție a băuturilor de 15 ani. Ne specializăm în a oferi clienților proiecte cheie în mâna pentru producția de băuturi (apă, suc, băuturi carbonatate, băuturi energetice, ceai frigider și altele) pentru sticle PET, conserve din aluminiu, sticle de sticlă.

Putem oferi următoarele servicii:

1-toate mașinile necesare pentru linia de producție completă

(sistem de tratare a apei / sistem de amestec / mașina de spalare, umplere și inchidere / imprimantă cu cod laser / mașina de etichetare / mașina de ambalare / transportator pentru sticle)

2-Furnizăm materii prime precum preformă, capac, conserveră, etichetă, film PE și alte accesorii

3-În ceea ce privește instalarea mașinilor, avem ingineri profesioniști care se deplasează pe loc, care vor finaliza instalarea și vor instrui inginerii și muncitorii dvs.

4-Poate să conceapă etichete, forma sticlelor și aranjamentul mașinilor conform atelierului dvs.

Comark Machinery conduce în domeniul R&D al ambalării băuturilor, oferind soluții complete. Dedicația față de cercetarea amont și aval asigură o gamă largă de produse.

Servind peste 30 de țări, Comark răspunde nevoilor industriilor precum cele ale băuturilor, aromelor, cosmeticii, berei, laptelei și farmaceuticelor. Prezența globală și versatilitatea consolidează poziția lor pe piață.

Comark se concentrează pe inovația tehnică, depunerea de brevete și consolidarea unei poziții de piata unice. Acest angajament îi menține în fruntea ambalării băuturilor.

Comark colaboră cu instituții de top pentru a analiza și integra tehnologia străină, optimizând designul și performanța pentru îmbunătățiri remarcabile.

14

Aug

14

Aug

14

AugMasa de umplere a sticlelor cu apă COMARK este concepută pentru a-accomoda o varietate de dimensiuni și tipuri de sticle cu apă. Poate manipula diferite forme de sticle, inclusiv sticle PET standard și mărimi personalizate, asigurând flexibilitate în producție.

Masa utilizează tehnologie avansată de umplere și controale precise pentru a asigura umplerea exactă. Are sisteme automate care reglementează debitul și poziționarea sticlelor, minimizând erorile și menținând niveluri consistente de umplere.

Capacitatea de producție variază în funcție de model și configurare. În general, masa este concepută pentru o producție în volum mare și poate gestiona cantități mari de sticle pe oră. Pentru detalii specifice privind capacitatea, consultați specificațiile produsului sau contactați echipa noastră de vânzări.

Da, masa este concepută pentru a se integra seamless cu liniile de producție existente. Are conectoare și interfețe adaptables care facilită instalarea ușoară și integrarea, sporind eficiența globală a producției.

Întreținerea rutieră include curățarea periodică a sistemului de umplere, inspectarea componentelor mecanice și calibrarea parametrilor de umplere. Mașina este livrată cu un ghid detaliat de întreținere, iar echipa noastră de asistență tehnică este disponibilă pentru o ajutor suplimentar.