Máquina Rotativa Automática de Etiquetagem com Cola Derretida a Quente OPP

Descrição

1.Requisitos do Cliente

|

Número |

Conteúdo |

Requisitos |

|

1 |

Material do produto/forma |

PET/frasco redondo |

|

2 |

Especificação do produto/tamanho |

|

|

3 |

Posição rotulada |

Corpo da garrafa |

|

4 |

Número de rótulos |

1 |

|

5 |

Material da etiqueta |

não transparente transparente |

|

6 |

Tamanho da etiqueta |

|

|

7 |

Posição de instalação |

Preenchimento em raft antes do preenchimento |

|

8 |

Capacidade |

12000-15000 APH |

2.Modelo Recomendado

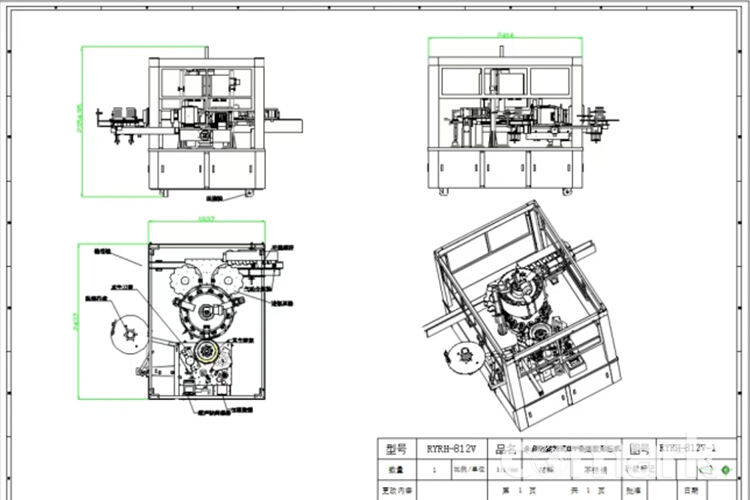

Máquina de Rotulagem com Cola Termofusível OPP RYRH-812V-2 Automática Rotativa

3.Composição do Equipamento

5.1 Configuração Básica e Marca dos Componentes Elétricos

Motor de servo: sistema de motor de servo de alta potência e alta inércia ABB

Unidade de servo: sistema de transmissão sincronizada ABB

PLC: BECKHOFF da Alemanha

Interface homem-máquina: tela colorida de 10 polegadas Schneider

Sensor de código de cor: sensor de código de cor SICK da Alemanha, detectando uma marca de cor específica no rótulo

Sensor de produto: interruptor fotoelétrico de detecção de alta velocidade SICK

Motor principal: Siemens

Inversor de frequência: DANFOSS

Dispositivo de correção: TECHMACH

Componentes de baixa tensão: FESTO, Schneider

Componentes pneumáticos: FESTO, MAC, ventilador de alta pressão de Taiwan

Codificador: codificador de alta velocidade e alta precisão SICK

Dispositivo de cola termofusível: caixa de cola desenvolvida independentemente

Sistema de desenrolamento: Maxcess sistema de desenrolamento a pó magnético dos EUA, garantindo a estabilidade e a tensão constante do desenrolamento

Sistema de lubrificação da máquina: um sistema de preenchimento automático de óleo importado da Coreia do Sul

5.2 Suporte: Aço inoxidável, rodízios universais, parafusos de ancoragem

5.3 Eixo: Os principais materiais utilizados são alumínio fundido e aço inoxidável fundido, e o eixo central é feito de alto desempenho 40Cr

5.4 Sistema de esteira: O sistema adota largura padrão de corrente de placas, o que permite uma conexão mais flexível;

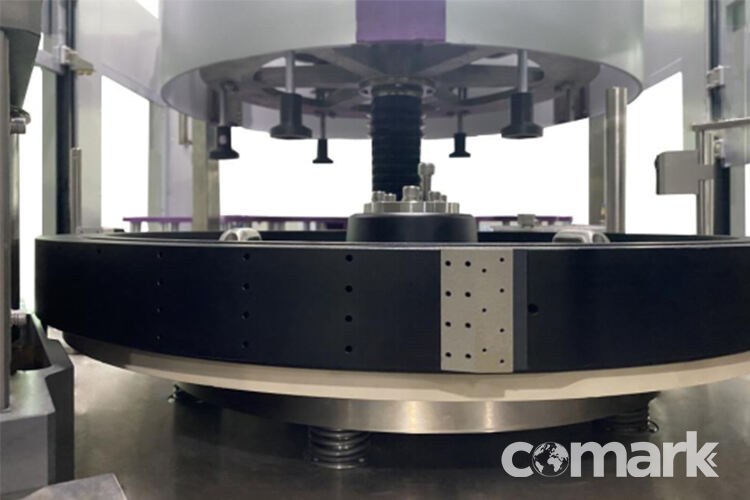

5.5 Conjunto de roda estrela: transferência suave dos produtos na linha de esteira para o eixo

5.6 Sistema de ajuste de elevação da estação: flexível para rotulagem de garrafas em diferentes alturas

5.7 Sistema da estação de rotulagem: um sistema de rotulagem que integra desenrolamento, alimentação de rótulos, corte de rótulos, colagem e prensagem de rótulos

5.8 Sistema de ajuste do interruptor de detecção de produto

5.9 Caixa de controle elétrico de aço inoxidável, botão à prova d'água, botão de parada de emergência

4.Características de Desempenho

1. O fotossensor detecta automaticamente a entrada das garrafas e o rótulo é alimentado automaticamente.

2. O rolo impulsionador da etiqueta alimenta automaticamente a etiqueta através do codificador e do sinal fotoelétrico, mantendo a etiqueta sempre em um estado tensionado.

3. O equipamento é totalmente automático e não requer cuidados especiais.

4. É provido com a função de detecção de etiquetas e possui a função de alarme quando o rolo de etiquetas termina.

5. O sensor de detecção de produto utiliza uma célula fotoelétrica de alta velocidade SICK da Alemanha.

6. Possui suporte ajustável para o sensor de detecção de produtos, permitindo ajustes rápidos dos pontos de detecção.

7. Corta as etiquetas antecipadamente usando uma ou duas lâminas, transfere as etiquetas para a posição pré-rotulagem por meio de um tambor de vácuo e, em seguida, cola as etiquetas. A etiqueta é suavemente aderida à superfície do frasco.

8. O sistema de alimentação utiliza um método de alimentação contínua para alcançar um rótulo mais rápido e estável.

9. Toda a máquina utiliza um sistema de lubrificação inteligente com injeção de óleo, o que torna a transmissão eficiente e aumenta a vida útil das peças de transmissão, como rolamentos.

10. O quadro da máquina é feito de aço inoxidável, proporcionando uma aparência limpa e durabilidade.

11. A rosca e a roda estrela de entrada do frasco adotam o conceito de desmontagem rápida, o que reduz eficazmente o tempo gasto na troca do tipo de garrafa.

Quadro & Aparência:

O quadro dos rolamentos utiliza aço carbono de alta qualidade com pintura antiferrugem para longa vida útil. As demais partes são fabricadas em aço inoxidável 304.

Gabinete de controle elétrico independente:

É à prova d'água, à prova de umidade e à prova de poeira, além de estar equipado com ar condicionado independente para dissipação de calor, permitindo assim adaptar-se a mais ambientes de trabalho e proteger melhor o equipamento, garantindo a segurança elétrica.

Estação de rotulagem com cola quente:

1. Utiliza um motor servo independente para desenrolar o rótulo, o corretor automático de desvio e o rolo servo independente cooperam para alimentar o rótulo e manter a precisão do corte dentro de 1mm. O tambor de sucção de vácuo do rótulo é controlado por um motor servo independente, e o sistema de cola desenvolvido internamente e o tambor de vácuo trabalham perfeitamente juntos para garantir a precisão do rótulo, e a operação de elevação elétrica é conveniente e economiza tempo.

2. O equipamento opera no modo automático. O inversor de frequência ajusta a velocidade de acordo com a quantidade de garrafas, e a configuração padrão é sem rotulagem sem garrafas, sem colagem sem rótulos.

Corretor de desvio:

O corretor automático de desvio trabalha com o rolo de rótulo servo independente para manter a precisão da aplicação do rótulo dentro de 0,3mm, e o ângulo de inclinação do rótulo inferior a 1°, garantindo a estabilidade do corte dos rótulos.

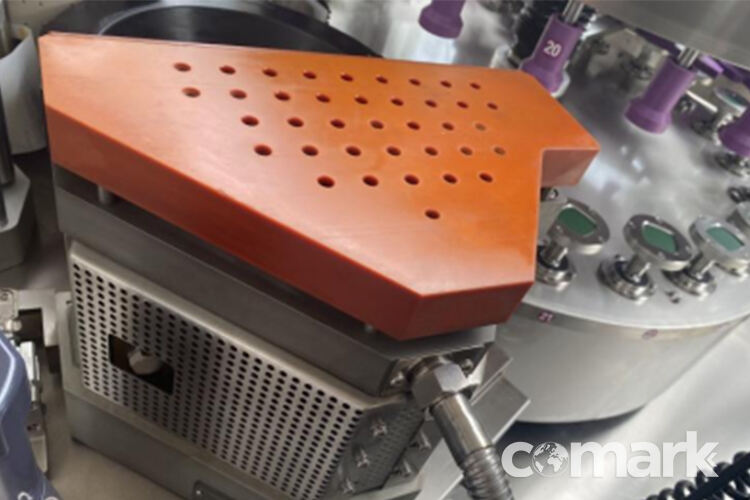

Tambor cortador de vácuo:

A faca de corte adota material especial da Alemanha, que é muito durável e resistente ao desgaste. Além disso, somos os primeiros na China a adotar a função de resfriamento a temperatura constante, permitindo que a lâmina opere em alta velocidade sem esquentar, o que prolonga sua vida útil. Isso também garante que a taxa de falha no rótulo seja inferior a 1/10.000.

Tambor de sucção de rótulos a vácuo e bloco de sucção:

Controlado por um motor servo independente, o tambor a vácuo e o tambor cortador coordenam-se suavemente durante a transição. O avançado design do circuito interno de vácuo do tambor garante uma sucção estável dos rótulos e elimina o fenômeno de queda de rótulos. Ele também está equipado com uma função de detecção de rótulos. Se o rótulo cair, ele emitirá um alarme e desligará.

O bloco de sucção monobloco possui alta precisão e resolve completamente o problema de baixa precisão nas costuras. Ele tem boa planicidade e aplicação uniforme de cola. A superfície é tratada especialmente com revestimento anti-aderente para resolver o problema de resíduos de cola. O material de liga de alumínio é durável e econômico, e o efeito de etiquetagem é mais bonito.

Rolo de cola:

É utilizado um rolo do tipo favo de mel para aplicação de cola, cuja espessura pode ser ajustada, e a quantidade de aplicação de cola é de 1,2 a 1,6 fios (cerca de 80.000 etiquetas/kg).

A tecnologia de recirculação de drenagem de fluidos para aplicação de cola foi desenvolvida independentemente, sem respingos ou resíduos de cola. A cola pode ser reutilizada para reduzir custos, e a fonte de calor não contatante dentro do rolo pode proteger eficazmente as etiquetas contra queimaduras. Além disso, rolamentos resistentes ao calor e materiais de dissipação de calor são utilizados para garantir uma operação estável.

Sistema de entrada sem riscos:

A tradicional rosca de entrada que arranhava as garrafas foi substituída pelo sistema de entrada sem arranhões.

Dispositivo de bloqueio:

Há um sensor instalado a 3 metros antes e depois do equipamento para detectar se o material da linha de produção está cheio. Quando há falta de material na seção anterior ou garrafas travadas na seção posterior, o PLC controlará imediatamente o cilindro para abrir e parar a garrafa ao receber o sinal, e o equipamento passará instantaneamente de alta velocidade para baixa velocidade ou estado de hibernação em standby para economizar consumo de energia do equipamento. Quando o sinal do sensor for recebido novamente, o bloco do cilindro será fechado. O equipamento passará automaticamente de baixa velocidade para alta velocidade e não requer operação manual.

Mecanismo de pressão da garrafa:

Adota-se uma estrutura de mola de tensão em três etapas para garantir elevação vertical, pressão uniforme nas garrafas e alta estabilidade. O ajuste de elevação elétrica economiza mão de obra e tempo.

Forma inferior:

1. Adota estrutura de desmontagem e montagem rápida para reduzir o tempo gasto na troca de tipos de garrafas. Após a correção do molde inferior de posicionamento pela primeira vez, você só precisa montá-lo em ordem, sem correção secundária.

2. O molde inferior com agulha de posicionamento mecânica gira em 3 círculos para encontrar o encaixe de posicionamento, de modo a alcançar um rótulo de posicionamento fixo preciso.

Interface dual de homem-máquina:

As telas sensíveis ao toque principal e auxiliar são ambas da marca Schneider. As interfaces e parâmetros entre as duas estão interconectados para controlar o equipamento. A tela auxiliar pode ser movida para facilitar o ajuste e o uso da máquina. O pessoal não precisa se mover para frente e para trás, economizando tempo de ajuste da máquina.

Sistema de lubrificação:

O sistema de lubrificação automática importado da Coreia é adotado. O intervalo de tempo da lubrificação automática pode ser ajustado na tela sensível ao toque, o que desempenha um bom papel na manutenção do equipamento e na extensão da vida útil do equipamento.

5.S segurança G garantia

Botão de parada de emergência, armário elétrico com função à prova d'água

Norma de design para sistemas de fornecimento e distribuição de energia (GB50052-95)

Norma de design de distribuição de baixa tensão (GB50054-95)

Código para construção e aceitação da instalação de equipamentos de transporte contínuo (GB50270-38)

RIS 10 segurança mecânica

RIS 15 proteção das partes móveis do dispositivo

Fatores de risco para parada súbita do RIS 58

Especificação da linha de alimentação: cabo RV com blindagem de 0.5 X5 núcleos, voltagem do sistema: 220V potência 2KW

Conduíte de PVC

Caixa de interruptores à prova d'água totalmente fechada

Terminal Phoenix

Código para construção e aceitação da instalação de equipamentos de transporte contínuo (GB50270-38)

Boa instalação, operação mecânica e elétrica

Resultados do relatório de recepção estática e dinâmica

parâmetros Técnicos

|

Número de estações de trabalho s : 12 |

|

Fonte de Alimentação: AC 380 V 50 Hz 20KW |

|

Capacidade: 12000-15000 BPH (sujeito à forma do frasco e rótulo) |

|

Método de ajuste de velocidade :variação contínua de velocidade |

|

Precisão de rotulagem: ±1.5mm (erro no tamanho da garrafa dentro de ±0.3mm) |

|

Diâmetro da garrafa: ≤φ 105mm |

|

Diâmetro interno do rolo de rótulos: φ152.4mm |

|

Diâmetro externo do rolo de rótulos: φ600mm |

|

Altura máxima do rótulo: 130mm |

|

Altura mínima do rótulo: 30mm |

|

Método de colagem: cola nas duas extremidades de cada rótulo |

|

Temperatura de colagem: 120~160℃ |

|

Material da etiqueta : Op , Filme pearlescente, filme composto de papel e plástico, rótulo de papel |

|

Fonte de ar: 5KG |

7.Lista de Principal E elétrico C ompo nentes

|

Item |

Marca |

Origem |

|

tela de interface homem-máquina de 10 polegadas |

Schneider |

França |

|

interface homem-máquina móvel de 7 polegadas |

Schneider |

França |

|

PLC |

Beckhoff |

Alemanha |

|

Motor servo de alimentação |

ABB |

Suíça |

|

Unidade de acionamento servo para alimentação |

ABB |

Suíça |

|

Servo motor |

Inovance |

China |

|

Servo-Drive |

Inovance |

China |

|

Módulo de Expansão Completo |

Inovance |

China |

|

Módulo de controle de temperatura |

Inovance |

China |

|

Sistema de correção e guia de desvio |

TECHMACH |

China |

|

Inversor |

Danfoss |

Dinamarca |

|

Sensor de Garrafa |

Doente |

Alemanha |

|

SENSOR DE ETIQUETA |

Doente |

Alemanha |

|

Contator AC |

Schneider |

França |

|

Relais |

Schneider |

França |

|

Fonte de alimentação comutável |

MeanWell |

TAIWAN |

|

Cilindro |

AIRTAC |

TAIWAN |

|

Motor de bomba de cola |

SPG |

Coreia do Sul |

|

Desligador |

Schneider |

França |

|

Interruptor de parada de emergência |

Schneider |

França |

|

Motor principal |

Siemens |

Alemanha |

8.Part s de C operado C clientes