Tá an Mhachan Fúilíochta Uisce COMARK bréige chun toradh ard-néamhspleách a sholáthar le príosúnas gan chothrom. Tá méadóir fúilíochta láidre a chomhléiriú a chur in iúl, atá i gcónaí don ghnás a thógál ar chúrsaí éagsúla agus cineálacha botún, ag cinntiú go bhfuil sé éifeachtach do phríomhchur slándála uisce. Cinntíonn oibríocht ar an droichead ard agus an méadú fíor go mbeidh na spriocanna tionscnamhaithe ag críochnú go hiomlán. Taispeánann comhaontas COMARK do choir, i ndeighin an chórais dian seo, a thacaíonn le rith fada le cúram íoctha nimhneach. Le fiabhs níos fearr agus comhéadan úsáideora ceanmhara, soláthraíonn an Machan Fúilíochta Uisce COMARK réiteach idéala do shruthaithe atá ag iarraidh dul chun cinn a n-ardchaighdeán fúilíochta agus cur i bhfeidhm faoin gcéad.

Tá na hiompair uisce ag COMARK faoi deara as a n-éifeachtacht. Tógtha le chur i gcás éifeachtacht neamhspleách ina chulloidh gach uisce, is féidir le hIompar Uisce COMARK an méid céanna den n-uisce a chur isteach i ngach ball. Is féidir leis an bhfógra bheith in ann cúpla míniú amháin ón gcumraím atá suite a phlé le heolais níos láidre ar shainmhínithe agus teicneolaíocht cumraím, mar sin cinntíonn sé go bhfuil gach ball lán leis an méid céanna den n-uisce, a dhulbannonn ach sin amháin, ach bíonn sé tábhachtach freisin chun éifeachtacht idir fhiúntais a thabhairt faoi láthair. Mar thoradh ar an obair seo, tugann COMARK réiteach dlighiúla do pháirtithe chun éifeachtacht agus éifeachtacht a fheabhsú sna bpriocess bottling uisce.

Is fianaise na n-eolais agus na gcuilíochtaí foirfe a bhaineann leis na hinnealláin léamh uisce a chruthaíonn COMARK ar chomhaid an chur chuige d'fhiúinniúchán a thabhairt. I measc na n-ábhar nua is déanaí i gcás teicneolaíocht léamh, tá Inneall Léamh Uisce COMARK ar fáil le heagairí níos príobháideacha nó ná bíonn agus le scagaire feabhraíochta féin a mheasaíonn éifeachtas iomlán. Mar aidhm amháin chun aithreán a fheabhsú agus chun comhráimeanna sa réimse seo a choinneáil, cuireann COMARK caitheamh trom ar phríomhchuspóirí taighde agus forbairt. Is é sin nach gcuirfidh siad ach go bhfuil a gcuid soláthar ar fáil don ábhar atá ag teastáil ón gcaighdeán lá inniu, ach freisin faoi shuim mar a bheidh ag teastáil amach anseo amárach, ag tabhairt freagraí éagsúla do dhlúthphlé agus forbairt.

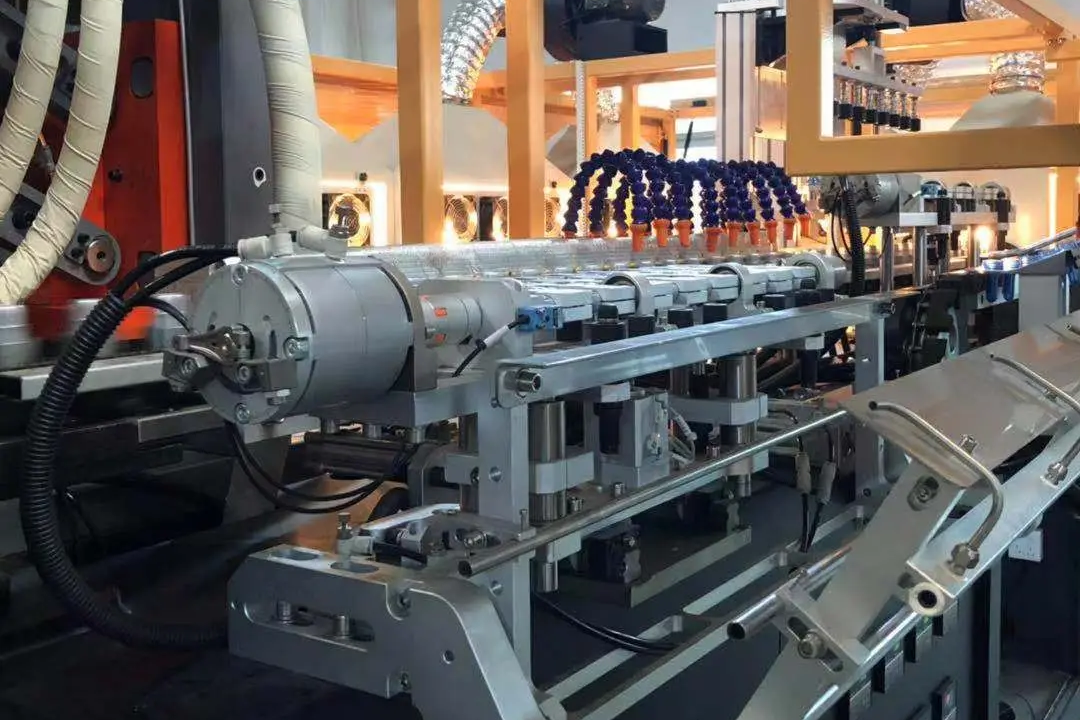

Chun ceartas ard a chur i bhfeidhm, feabhsach agus deisbhéalacht, intregráiltear teicneolaíocht nua-aimseartha ag COMARK san aghaidh na ngheilt uisce. Usáideann an mhinicín mecanais fillte ar staighre nua-aimseartha a chuireann torthaí suntasacha ar fáil don ghnéithe éagsúla agus cineálacha botún. Is féidir léiriúchánanna den scoth agus rialtaí aithníochta a úsáid chun tacú le feabhsuithe agus cúpla earráid nó scamaileadh freisin. Trí thabhairt faoi úsáid na n-innsciúcháin teicneolaíochta is déanaí, déantar cinntiú ag COMARK go bhfuil a gcéimeanna fillte uisce níos éifeachtaí ná aon eile, ag cinntiú go bhféadfaidh busaithe a phróiseas tuarascála a fheabhsú agus cásanna ceartas a chosaint.

An chóir go bhfuil COMARK taispeáin a comhfhiosú do dhlúsacht i gcomhlachtaí uisce a chur ar fáil tríd an gcruthaitheacht agus an bhfoirgneamh acu. Tá an Mhinicíocht Uisce COMARK déanta as mhatéarlaí ardleibhéal le heangacha láidre a chuirfear isteach i gcás gur féidir leo obair a dhéanamh faoi shonrú don n-ám chun siúd, fiú i gcásanna bródúla. Mar shampla, tá crócaire láidre aici a fhéadfadh obair go leanúnach gan cúl rith a thabhairt go minic, mar sin is lú an ama atá de dhíth chun cuir os cionn é. Is é seo an chúis don dlúsacht a bheith níos lú agus tuiscint níos mó, mar sin is fearr rogha don chomhlachtaí atá ag lorg córas fillteánach sna háiteanna idir 10 agus 20 mbliana.

Tá Zhangjiagang COMARK Machinery Co Ltd ag obair i réims éagsúil den eispord nuaolaíochta ar fud na cruinne déag bliain anuas. Táimid in ann custaiméirí a chur chun cinn le haghaidh tionscnaimh iomlán (úisce, fuisce, dréimire glas, dréimire neamhspleách, dréimire n-ghnó, thé fhuar agus eile) trí bhlianta na n-earraí PET, cóin alabainne, agus bóthar glas.

Is féidir linn na seirbhísí seo a sholáthar:

1-gach uirlis de chuid na líne tionscnamh iomlán

(córas úsáide úisce / chóras míreálaithe / comhaireamh léiriúcháin sciotála / clóscríobh laistigh / uirlis clibithe / uirlis pacaíochta / bothar earra)

2-Forbróga tomhaltóireachta a sholáthar mar shampla preform, ghlac, cóin, clib, film PE agus tuilleadh

3-I gcás an tsuiteáil na n-uirlise, tá mion-innealtóir spéiscthe againn ag dul go háitiúil, bíonn siad ag críochnú an suiteála agus ag foghlaim do mhion-innealtóirí agus do phobal

4-is féidir linn clib, cruth botún agus leagan amach na n-uirlise a dheimhniú de réir do sheasamh

Tá Comark Machinery ag tosú leis an ionchur agus forbarthu pacáidí diúsca, ag cur i gcás tuilleadh. Déantar an-tacaíocht don ionchur uachtarach agus íochtarach chun séimpeil iomlán a shonrú.

Ag seirbhísú 30+ tír, cuireann Comark ceadúnas don liosta beatha, blasanna, cósmadachta, beoir, bainne, agus sláinte. Tugann an reachtaíocht idirnáisiúnta agus an feidhmíocht éifeacadh leo a gcás mar phost a fheabhsú san mballstáit.

Tá foirmiúchán teicneolaíochta ag Comark mar phríomhphobal, ag glacadh patainte agus ag forbairt staidéar ábharú don margad. Is é seo an comhaontas a choinníonn iad faoi láthair sa phacáid diúsca.

Tá Comark ag obair i gcomhpháirt le n-iasuithe ar cheann, chun eolaíocht thionscnamhacha ón gceantar eile a bhailiú & a chur i bhfeidhm, ag oiliúint an díbhúnachas agus an n-éifeachtacht chun fothbunúsanna iontacha a bhaint amach.

14

Aug

14

Aug

14

AugTá an Mhachan Fúilíochta Uisce COMARK cruthaithe chun rangoicéad éagsúil sócmhainní agus cineálacha botún uisce a fhoilsiú. Is féidir leis linniúchán éagsúla, lena n-áirítear botún PET stairiúil agus méairiúcháin saincheaptha, a phróiseáil, cinnteach ag baint uaireas i bhfoirmnóid phróiseála.

Úsáideann an mhachan teicneolaíocht fúilíochta láithreach agus riaghlóidí níos príobháideach chun cinntiú ar fhilliú intinneach. Tá córais idirghníomhacha aici a rialaíonn luas an srutháin agus comhréireacht na n-botún, ag minimitheach earráidí agus ag cinntiú leibhéal filliú一致性.

Athraíonn an cumas phróiseála de réir an módéil agus an chumrú. Ginearálta, tá an mhachan cruthaithe don pháirc phróiseála uafásach agus is féidir leis linniúchán mór a phróiseáil gach uair. Chuir ar fheidhm na hábhar speisialta nó bíogfaigh liomár timpeallacht nó ceangail leár foirgnimh tímhailt.

Is ea, cruthaithear an mhachan chun dul i ngleic go soiléir le línte próiseála atá ann cheana féin. Tá ceanglaithe agus comhéifeadh aici a chur in iúl go héasca agus dul i ngleic, ag cinntiú ar feabhsuithe phróiseála iomlán.

Tabharfaidh comhaltaí cothrom le feabhsú ar fadhbhanna faoi láthair agus pléfidh siad le polasaithe nua a chur i bhfeidhm. Tá treoir iontach mí-dhuine ar fáil leis an mbiachán, agus táimid linn do chuid cabhrach.